Research Progress Of Magnetic Field Annealing Effect Of Nanocrystalline Soft Magnetic Alloys

Changes in Alloy Crystallization Behavior and Magnetic Domain Structure of Nanocrystalline Soft Magnetic Alloys After Magnetic Field Annealing. Compared with non-magnetic annealing, magnetic field annealing can refine grains and increase the nucleation rate of nano-grains, thereby increasing the proportion of crystal phase in the alloy and improving the soft magnetic properties; after magnetic field annealing, the alloy In the magnetic domain structure, the pinning sites disappear, the magnetic domain interface is clear, and most of them are distributed along the direction of the external field.

Nanocrystalline soft magnetic alloys represented by Finemet, Nanoperm, and Hitperm have developed into an indispensable and important component in the field of soft magnetic materials since their appearance in the late 1980s. By adjusting the alloy composition, the nanocrystalline soft magnetic alloy can obtain the best soft magnetic properties. Finemet with FeCuNbSiB as the main component has a magnetic permeability as high as 105 and a coercive force of less than 1 A/m. Due to its low Curie temperature (about 300 ℃), its application at high temperature is greatly limited. In order to overcome this weakness, an appropriate amount of Co was added to Finemet, and the amorphous Curie temperature of the alloy was raised to 450 °C, which greatly expanded the temperature use space of nanocrystalline alloys. However, due to the addition of high magnetostrictive element Co, the overall magnetostriction of the alloy increases, and the soft magnetic properties of the alloy drop sharply at room temperature. In order to reduce the magnetostriction of the alloy, the negative magnetostrictive element Ni was added to the alloy, although the room temperature performance of the alloy was improved to some extent, but its Curie temperature decreased significantly.

In addition to adjusting alloy composition, magnetic field annealing is also widely used to improve the soft magnetic properties of nanocrystalline alloys. Magnetic field annealing is often used in the heat treatment of alloy materials, that is, an external magnetic field is applied during the heat treatment of the alloy, so that the magnetic atoms inside the alloy are rearranged due to the influence of the external magnetic field during the diffusion process, and a new atomic arrangement or magnetic domain structure. Common magnetic field annealing methods include: longitudinal magnetic field annealing, transverse magnetic field annealing, rotating magnetic field annealing and pulsed magnetic field annealing, etc. Due to the simple operation and avoiding the disadvantages of high economic cost caused by adjusting the composition, the research on the magnetic field annealing effect of nanocrystalline soft magnetic alloys has become one of the hot spots in the research of soft magnetic alloys. Moreover, magnetic field annealing is gradually applied to the heat treatment of ferrite soft magnetic materials.

Previous studies on the magnetic field annealing effect of nanocrystalline soft magnetic alloys mostly focused on the changes in the crystalline magnetic properties of the alloy after magnetic field annealing, and formed more systematic conclusions, such as: After longitudinal magnetic field annealing, the hysteresis loop of the alloy is Rectangularization, coercivity and magnetic loss are significantly reduced; after transverse magnetic field annealing, the hysteresis loop is narrow and smooth, and the residual magnetic induction intensity is significantly reduced. In recent years, research on magnetic field annealing of nanocrystalline soft magnetic alloys has mainly focused on: the effect of magnetic field annealing on the crystallization behavior of nanocrystalline soft magnetic alloys, the effect of magnetic field annealing on the magnetic domain structure of nanocrystalline soft magnetic alloys, etc.

1. Effect of magnetic field annealing on the crystallization behavior of nanocrystalline soft magnetic alloys

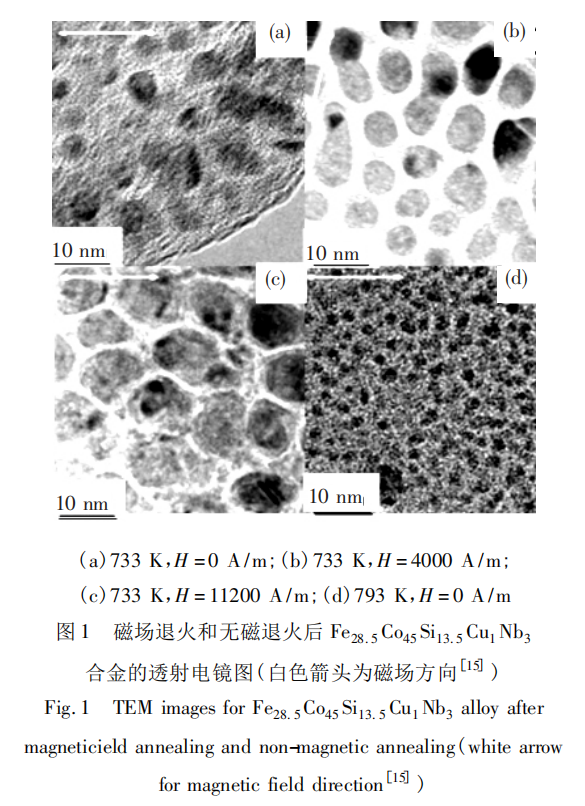

P.Marín et al. Fe28. 5 Co45 Si13. The 5 Cu1Nb3 amorphous strips were annealed in magnetic field and non-magnetic at 733 K and 793 K, and analyzed by transmission electron microscope, as shown in Figure 1.

The study found that during the annealing process, the external magnetic field promoted the size of the nanocrystalline grains. Under the condition of 733 K, the size of the formed grains was about 6 nm when there was no external magnetic field; when a magnetic field of 4000 A/m was applied , the grain size increased to 10 nm, and the grains tended to grow along the direction of the external field; further increasing the magnetic field to 11200 A/m, the grains grew rapidly to 25 nm. In the absence of an external magnetic field, increasing the annealing temperature to 793 K, it can be seen that the randomly distributed grains increase, and there is no grain aggregation and directional arrangement.

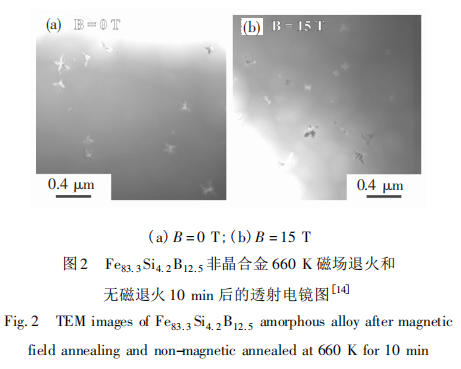

R.Onodera et al. found that after non-magnetic annealing at 660 K, a small amount of soft magnetic nano-grains were distributed in Fe83.3 Si4.2 B12.5 amorphous alloy; when a strong magnetic field of 15 T was applied, the number of nano-grains increased significantly, and the crystal phase in the alloy The proportion in the increase. It can also be seen that there is no significant change in the precipitated grain size under the two annealing conditions. See Figure 2. Therefore, the main reason for the increase in specific gravity of alloy crystals after magnetic field annealing is the increase of grain nucleation rate rather than the increase of grain size.

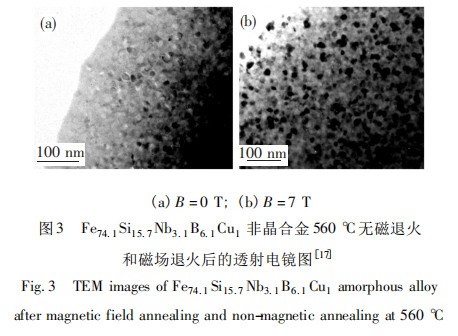

Madygundo et al. Fe74. 1 Si15.7Nb3. 1B6. The 1Cu1 amorphous alloy was subjected to non-magnetic annealing and magnetic field annealing at 560 °C, as shown in Figure 3. It can be seen that under the condition of no external magnetic field, the size of nanocrystalline grains precipitated by the alloy is about 15 nm; after applying a strong magnetic field of 7 T, the size of nanocrystalline grains is refined to 7-8 nm. This result is consistent with P. The opposite results were obtained by Marín etal.

For R Madygundo et al. and P. According to the experimental results of Marín et al., we are more inclined to the former. After the alloy is annealed in a magnetic field, the soft magnetic properties are improved. The excellent soft magnetic properties of nanocrystalline alloys come from the magnetic exchange coupling between ultrafine grains. On the premise that the grain size is small, the more grains, the stronger the exchange effect, and the soft magnetic properties of the alloy are also stronger. Optimize accordingly. Considering that the coercive force HC is proportional to the sixth power of the grain size D, when the grain size increases, the soft magnetic properties of the alloy will decrease.

2. Effect of magnetic field annealing on magnetic domain structure of nanocrystalline soft magnetic alloy

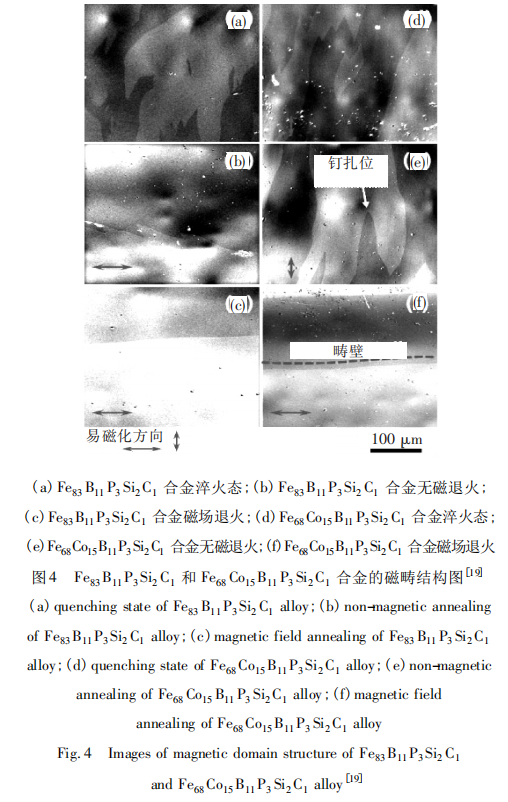

The change of magnetic domain structure is another focus of the magnetic field annealing of nanocrystalline soft magnetic alloys. At present, the magneto-optic Kerr microscope technique is mostly used to observe the magnetic domain structure of the alloy. Zhao et al. studied the magnetic field annealing effect on Fe83-xCoxB11P3 Si2C1 (x = 0 ~ 20) amorphous alloy, and observed and analyzed the magnetic domain structure of the alloy after quenching, 663 K non-magnetic annealing and magnetic field annealing, as shown in Figure 4 Show.

The study found that due to the existence of large internal stress, the distribution of magnetic domains in the alloy is extremely irregular; after annealing at 663 K, there are still pinning sites in the alloy, which is not conducive to the improvement of the soft magnetic properties of the alloy; during the annealing process In this case, when an external magnetic field of 200 Oe is applied along the stripe direction, the magnetic moment direction of the magnetic domain will be arranged along the direction of the external field, the magnetic domain wall will gradually disappear, the pinning effect will almost disappear, and the domain interface will be arranged linearly and neatly. remain in the alloy at the end of annealing. It can be seen that the magnetic field annealing makes the internal magnetic moment of the alloy linearly arranged, and the easy axis of magnetization is induced in the direction of the external magnetic field. If magnetization is carried out in this direction, a 180° displacement will more easily occur, and this domain wall displacement reduces the magnetostriction or magnetoresistance to almost zero. Therefore, after magnetic field annealing, the magnetostriction or magnetoresistance of the alloy will be significantly reduced.

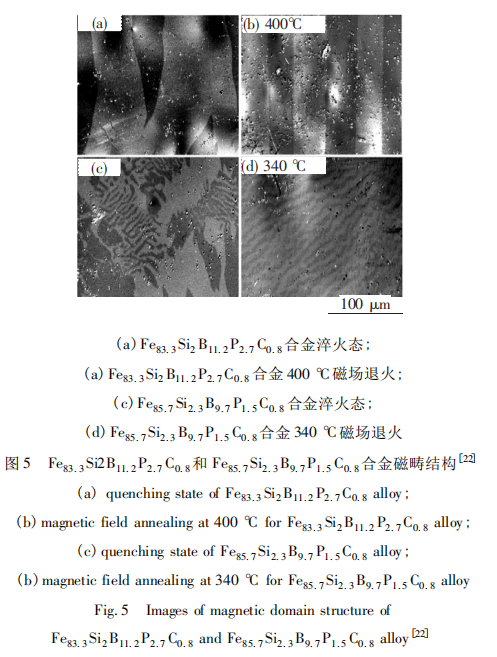

Li etal on Fe83. 3 Si2B11. 2 P2. 7 C0. 8 amorphous alloy and Fe85. 7 Si2. 3B9. 7P1. 5C0. 8 amorphous alloy was studied by magnetic field annealing, and the change of magnetic domain structure was analyzed, as shown in Figure 5. For Fe83. 3 Si2B11. 2P2. 7C0. 8 alloy, both in the quenched state and after magnetic field annealing, show a relatively regular striped magnetic field. However, there are obvious pinning sites in the quenched state, and the pinning centers disappear after magnetic field annealing, and the stripe-like magnetic domain structure is more regular, and the alloy is more easily magnetized along the stripe direction. Fe85. 7 Si2. 3B9. 7 P1. 5 C0. The magnetic domain structure of alloy 8 is irregular whether it is quenched or annealed by magnetic field. In contrast, magnetic field annealing reduced the branched magnetic domain structure to some extent.

3. Conclusion

Combined with the research results of magnetic field annealing, the effects of magnetic field annealing on the crystallization structure and magnetic domain structure of nanocrystalline soft magnetic alloys are reviewed. Compared with non-magnetic annealing, magnetic field annealing can refine the grain size, accelerate the nucleation rate of grains, and increase the number of nanocrystalline grains. Magnetic field annealing is beneficial to the enhancement of magnetic exchange coupling between grains in the alloy, and plays a role in optimizing the soft magnetic properties of nanocrystalline soft magnetic alloys. After magnetic field annealing, the magnetic domain structure changes significantly, the pinning site disappears, and the magnetic domains are arranged neatly along the direction of the external field. This directional arrangement can reduce the magnetostriction or magnetoresistance of the alloy in this direction to almost zero. Optimal soft magnetic properties of the alloy. However, in the study of the magnetic field annealing effect of nanocrystalline soft magnetic alloys, there are few reports on theoretical analysis, and further research is needed to theoretically explain the microcosmic mechanism of the magnetic field annealing effect.

Heat Treatment Process Of Extrusion Die Current Stress Annealing of Iron-based Nanocrystalline Alloys Mesh Belt Continuous Heat Treatment Furnace Production Line

Contact us

Your email address will not be published. Required fields are marked *