Effect of Secondary Transverse Magnetic Field Heat Treatment on Soft Magnetic Properties of FeSiBCuNb Nanocrystalline Magnetic Cores

1. Effect of secondary transverse magnetic annealing temperature on phase structure of FeSiBCuNb alloy

When the magnetic core undergoes conventional nitrogen annealing (NA) treatment or hot isostatic pressing, due to the residual stress caused by thermal shock and its own bending stress, the internal structure is in a metastable state, and the magnetic domain distribution is non-uniform, so Further heat treatment is required to remove residual stress, refine the uniform magnetic domain structure, and improve the high-frequency magnetic properties of the core. Magnetic field heat treatment can refine magnetic domains and adjust the induced anisotropy constant Ku, which affects the shape of the hysteresis loop [37]. Therefore, the transverse magnetic heat treatment process is used to perform secondary annealing treatment on the properties of 1K107 series nanocrystalline magnetic cores. The selected annealing temperature is 380 ℃ ~ 520 ℃, and the holding time is 120 min.

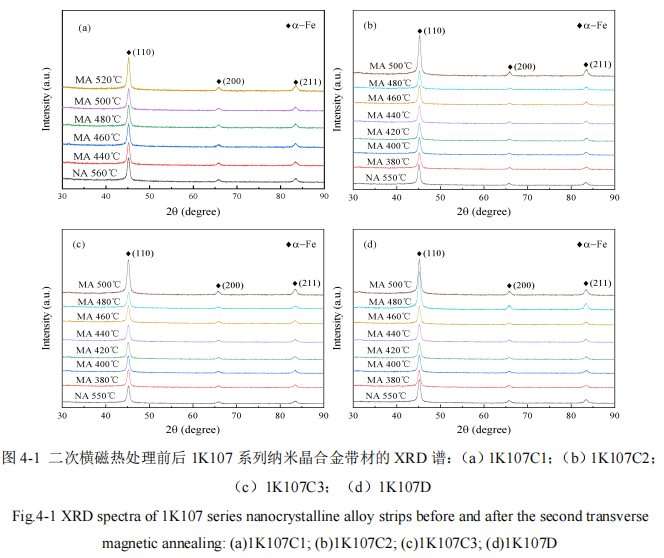

The XRD spectra of 1K107 series nanocrystalline alloy strips before and after secondary transverse magnetic heat treatment (MA) are shown in Fig. 4-1(a-d). According to the Scherrer formula, the grain size of the sample is calculated to be in the range of 13-15 nm, within the error range, indicating that the annealing treatment below the crystallization temperature Tx1 basically does not affect the grain size of the alloy. The volume fraction of the crystalline phase can be calculated by the peak intensity value of XRD, and the peak intensity of the crystallization peak can reflect the precipitation amount of the crystalline phase.

In the same alloy, the higher the intensity of the main peak, the higher the crystal structure content. From Figure 4-1(a-d), it can be found that 1K107C1, 1K107C2, 1K107C3, and 1K107D alloys start to precipitate crystal phases at 520 °C, 500 °C, 500 °C, and 480 °C, respectively, and the content of crystallized phases will change significantly. These alloys will continue to form new crystals when annealed above a certain annealing temperature (this temperature is lower than Tx1), this temperature is the glass transition temperature Tg.

2. Effect of secondary transverse magnetic annealing on the soft magnetic properties of FeSiBCuNb alloys

2.1 The effect of annealing temperature on the coercive force of the magnetic core

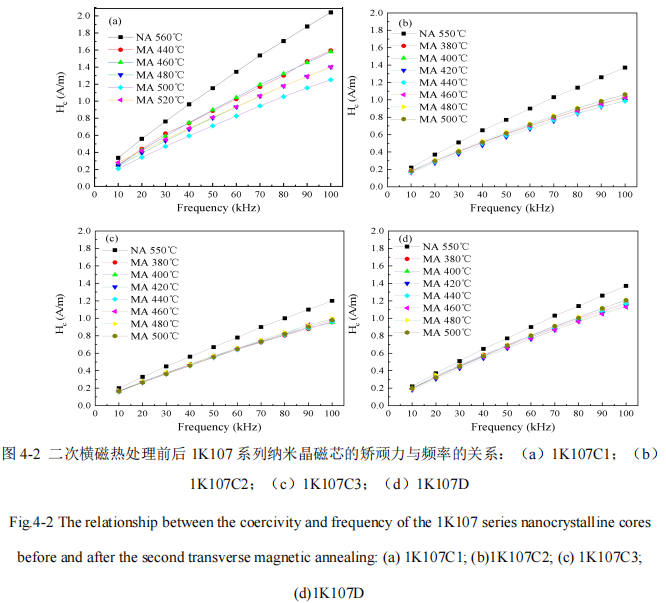

The coercive force can reflect the difficulty of magnetization of the alloy. After the magnetic field heat treatment, the magnetic domain arrangement is more uniform and the magnetic domain structure is more stable. There are no less than five factors affecting the coercive force, which can be represented by Hc (short program), Hc (surface), Hc(i), Hc(σ), and Hc (relaxation), which correspond to short-range ordered regions , surface roughness, intrinsic structure, magnetostrictive effect and relaxation effect and other influencing factors. Since λs≈0 for Finemet alloy, Hc(σ) can be almost neglected. Figure 4-2(a-d) shows the coercive force versus frequency curves of the 1K107 series nanocrystalline cores before and after secondary transverse magnetic heat treatment. It is found from the figure that the coercive force of the samples subjected to magnetic field heat treatment is lower than that of the nanocrystalline magnetic core without magnetic field annealing. This is because under the joint action of the external magnetic field and annealing, the residual internal stress is eliminated, resulting in structural relaxation, and the internal magnetic domain structure tends to be stable. Coercivity minima in the 10-100 kHz band for the four strip cores Compared with the cores before the respective transverse magnetic annealing, the secondary transverse magnetic heat treatment reduces the coercivity of the cores in the 10-100 kHz band.

When 1K107C1~1K107D strip cores are not annealed twice, their coercive forces at 100 kHz are 1.84 A/m, 1.21 A/m, 1.20 A/m, 1.37 A/m respectively; ℃, 440 ℃, 420 ℃, 420 ℃ after the secondary transverse magnetic annealing, the coercive force decreased to 1.25 A/m, 0.98 A/m, 0.96 A/m, 1.14 A/m, respectively, decreased by 32.1%, 19.0%, 20.8%, 16.8%. Of the four strip cores, the 1K107C3 strip core has the lowest coercive force at 10-100 kHz.

From Figure 4-2 (a-d), we can see the relationship between the coercivity and temperature of the 1K107 series alloy core after the secondary transverse magnetization annealing. It can be found that with the increase of transverse magnetization annealing temperature, 1K107C1 increases first and then decreases, because the stress is easy to cause abnormal phenomenon. However, the coercive force of other ribbon cores at a specific frequency is relatively stable in the range of increasing annealing temperature, showing a law of first decreasing and then increasing.

In addition, the coercive force of 1K107C1 nanocrystalline magnetic core varies greatly with temperature, from the maximum value of 1.60A/m to the minimum value of 1.25A/m at 100kHz, and the variation range is 0.35A/m. 1K107C1 strip-wound magnetic core has a small curvature diameter and a high lamination coefficient, resulting in macroscopic stress, and the temperature has a greater influence on its coercive force. The lower the force.

2.2 Effect of annealing temperature on core effective permeability

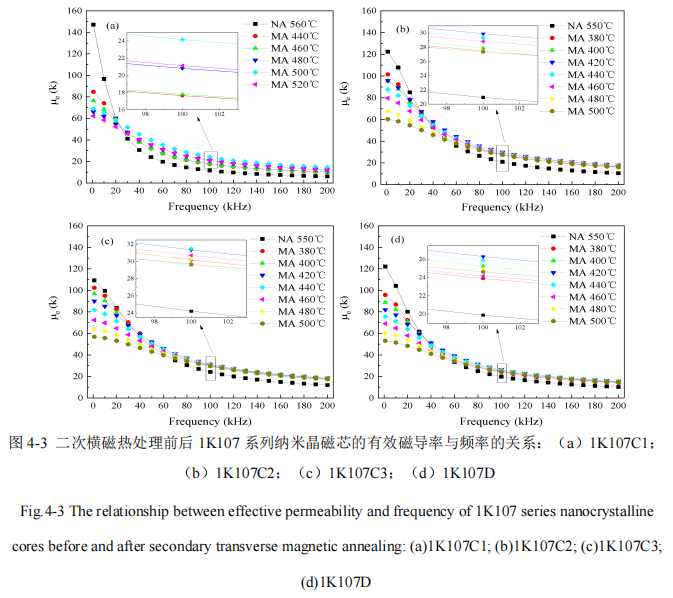

In iron-based nanocrystalline magnetic cores, the main factors for the deterioration of magnetic permeability with increasing frequency come from eddy current loss, magnetic domain rotation, and magnetic domain wall motion. Figure 4-3(a-d) shows the relationship between effective permeability and frequency before and after secondary transverse magnetic heat treatment of 1K107 series nanocrystalline cores. It can be seen from the figure that as the frequency of the AC signal increases, the effective permeability of the 1K107 series nanocrystalline cores decreases rapidly, which is mainly related to the frequency dispersion of the permeability [49, 54].

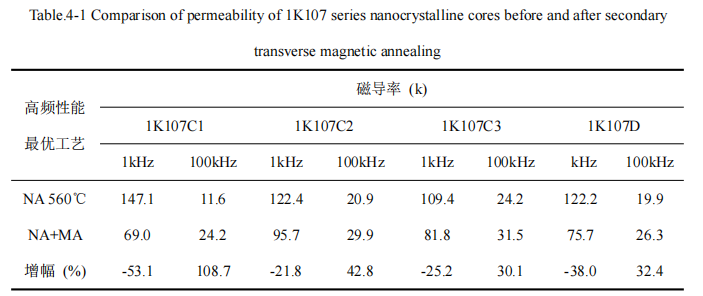

Table 4-1 is a comparison of the effective permeability of the 1K107 series nanocrystalline magnetic cores before magnetic field heat treatment and the magnetic permeability of the high-frequency optimal process of the magnetic core after the second transverse magnetic annealing. It can be seen from the table that the effective permeability of the 1K107C3 nanocrystalline magnetic core at 100 kHz is higher than that of the other three strip magnetic cores, and the value can reach 31.5k. The permeabilities at 1 kHz and 100 kHz for the two heat treatments are derived from the nanocrystalline cores at their respective optimal annealing temperatures for high frequency performance. At the same frequency, the effective permeability of the samples subjected to secondary transverse magnetothermal annealing is higher at high frequencies than that of samples crystallized only after nitrogen heat treatment, but it becomes lower at low frequencies. The optimal transverse magnetic annealing temperatures for 1K107C1, 1K107C2, 1K107C3, and 1K107D strip cores at high frequencies are 500 °C, 420 °C, 440 °C, and 420 °C, respectively.

At 1 kHz, the effective permeability of 1K107C1, 1K107C2, 1K107C3, and 1K107D nanocrystalline cores without secondary transverse magnetic annealing are 147.1k, 122.4k, 109.4k, 122.2k; After annealing, their effective magnetic permeability decreased to 69.0k, 95.7k, 81.8k, 75.7k, which decreased by 53.1%, 21.8%, 25.2%, and 38.0%, respectively, and the effective magnetic permeability of 1K107C2 changed at this frequency minimum.

At 100 kHz, the effective permeability of 1K107C1, 1K107C2, 1K107C3, and 1K107D nanocrystalline cores without secondary transverse magnetic annealing are 11.6k, 20.9k, 24.2k, 19.9k respectively; After annealing, their effective permeability increased to 24.2k, 29.9k, 31.5k, and 26.3k, which increased by 108.7%, 42.8%, 30.1%, and 32.4%, respectively, so the secondary transverse magnetic annealing significantly improved the 1K107C1 nanocrystalline The high frequency effective permeability of the core. Among them, the 1K107C3 nanocrystalline magnetic core has the largest high-frequency effective permeability.

From Figure 4-3(a-d), it is found that the effective permeability of the four strip cores at 1 kHz decreases with the increase of annealing temperature, while the effective permeability at 100 kHz presents a gradual increase with the increase of annealing temperature. The law of decreasing after increasing is the result of the joint effect of the induced anisotropy number Ku of the magnetic core and the magnetization mechanism. First, after the crystallized Fe-based alloy is annealed in a magnetic field, the induced anisotropy constant Ku will increase, and Ku will also increase with the increase of the magnetic field annealing temperature [71]. Under static or low frequency conditions, Fe-based nanocrystalline alloys are basically not affected by the dispersion of magnetic permeability, and their low-frequency magnetic permeability will theoretically decrease, which is consistent with the results in Figure 4-3 (a-d). Second, the main magnetization mechanism of Fe-based nanocrystalline alloys before and after magnetic field heat treatment is transformed from magnetic domain wall movement to magnetic domain rotation, and transverse magnetic annealing induces the transverse easy axis. According to Equation (1.5) and Equation (1.6), the magnetic permeability of Fe-based nanocrystalline alloys annealed by conventional nitrogen protection at alternating frequency is mainly affected by fc, and the magnetic permeability of Fe-based nanocrystalline alloys annealed by magnetic field is mainly affected by fDR. Ground, fc<fDR, so the high-frequency effective permeability of 1K107 series nanocrystalline alloys increases after magnetic field annealing. Conducting magnetic field heat treatment at a suitable annealing temperature can refine the uniform magnetic domain structure, reduce the magnetic domain relaxation time, and improve the magnetic moment deflection sensitivity, which can improve the high-frequency permeability of the 1K107 series magnetic core.

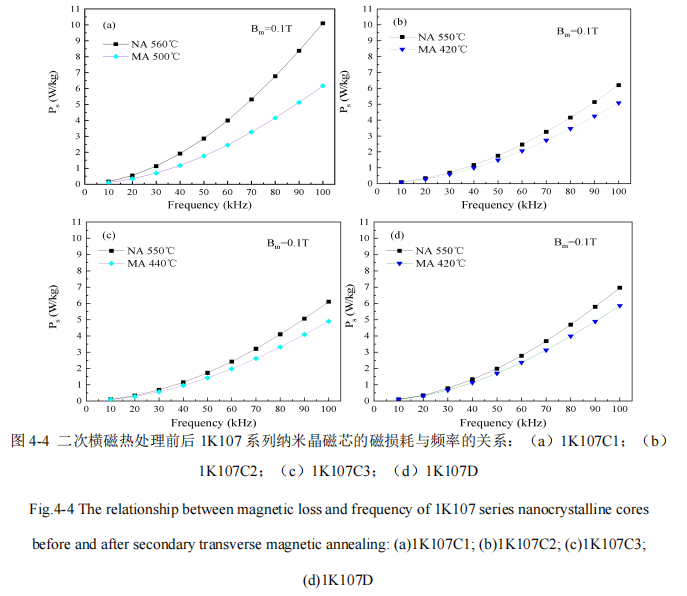

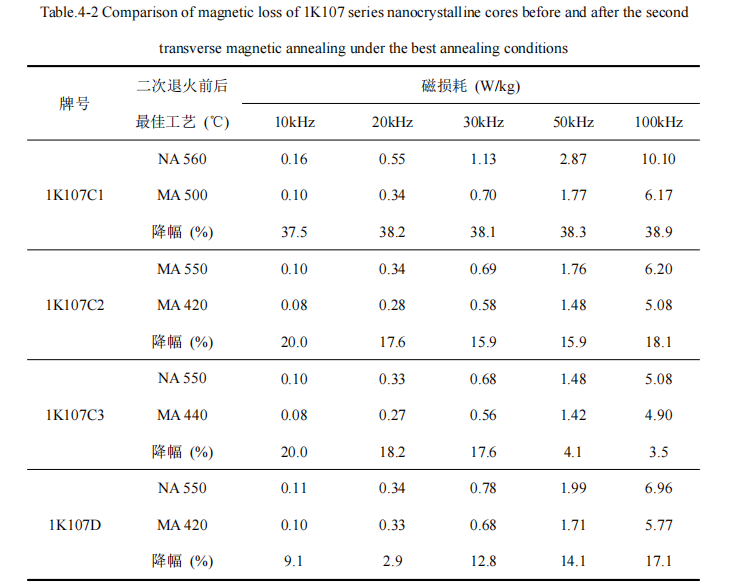

2.3 Comparison of magnetic loss before and after secondary transverse magnetic annealing

Figure 4-4(a-d) shows the relationship between magnetic loss and frequency of 1K107 series nanocrystalline cores before and after secondary transverse magnetic heat treatment. It can be seen from the figure that the magnetic loss of the 1K107 series nanocrystalline magnetic cores will decrease before and after the second transverse magnetic annealing, and the drop rate is relatively large. Table 4-2 is the data comparison of the magnetic loss of the 1K107 series nanocrystalline magnetic core before and after the second transverse magnetic annealing, in which the magnetic loss of the magnetic core sample with the best annealing temperature under the two heat treatment methods is selected.

It can be seen from Table 4-2 that at 10 kHz, the magnetic losses of 1K107C1~1K107D strip cores without secondary transverse magnetic annealing are 0.16 W/kg, 0.10 W/kg, 0.10 W/kg, and 0.11 W respectively /kg; after the second transverse magnetic annealing, the magnetic losses were reduced to 0.10 W/kg, 0.08 W/kg, 0.08 W/kg, 0.10 W/kg, which were reduced by 37.0%, 20.0%, 20.0%, 9.1 %.

By comparison, it is found that after the secondary transverse magnetic annealing of the 1K107C1 strip core, its magnetic loss decreases greatly in the 10-100 kHz frequency range, which is related to the large initial residual stress of the core after crystallization and the residual residual stress of the core after magnetic field annealing. It is related to the substantial elimination of the stress; the magnetic loss of the 1K107C3 strip core changes little at high frequencies before and after the second transverse magnetic annealing.

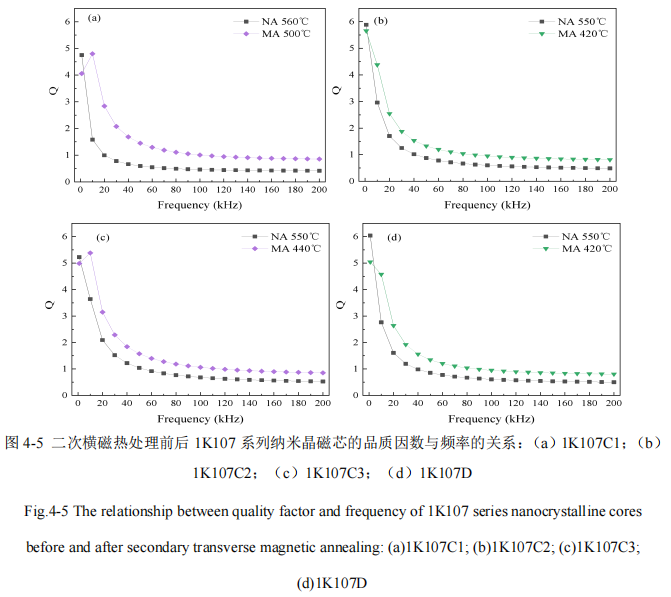

2.4 Comparison of core quality factors before and after secondary transverse magnetic annealing

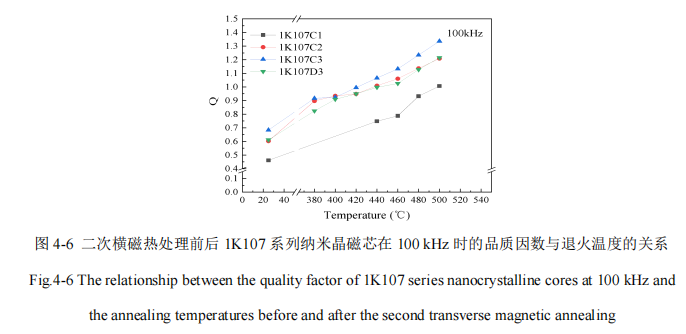

Figure 4-5(a-d) shows the quality factors of 1K107 series nanocrystalline magnetic cores before and after the second transverse magnetic annealing. It can be seen from Figure 4-5 (a-d) that the quality factor Q of the four strip cores of the 1K107 series decreases gradually with the increase of the frequency, and the cores after the secondary transverse magnetic annealing have a Q of f>10 kHz. The values are higher than those of the cores that have only undergone conventional nitrogen protection heat treatment, indicating that the secondary transverse magnetic heat treatment can improve the performance of Fe-based nanocrystalline cores.

It can be seen from Figure 4-6(a-d) that at 100 kHz, all 1K107 series strip cores within the annealing temperature of 380~500 ℃, with the increase of temperature, the Q value gradually increases. This gradual change law is directly related to the change of low-frequency effective permeability with the transverse magnetic annealing temperature, because the Q value represents the ratio of the core energy storage to energy consumption, and the inductance value corresponding to the effective permeability reflects the magnetic flux density. The energy storage capacity of the core. As mentioned above, there are mainly five kinds of coercivity. In a certain temperature range, the high temperature releases the stress more thoroughly, stress relaxation occurs, and Hc (relaxation) decreases, so the hysteresis loss is reduced and the quality factor is improved. . For 1K107C1~1K107D strip cores, their high-frequency (100 kHz) quality factor Q values before magnetic field annealing are 0.46, 0.60, 0.68, 0.61, respectively, and rise to 1.01, 1.21, 1.37, 1.22, an increase of 119.6%, 101.7%, 101.5%, 100.0%. Among the 1K107 series of strip cores, the 1K107C3 strip core has the highest quality factor for high frequency (100 kHz).

2.5 Comparison of impedance before and after the second transverse magnetic annealing

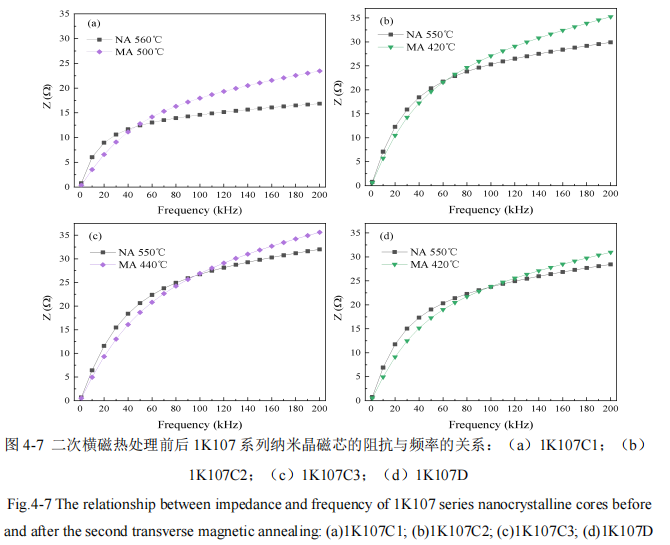

Figure 4-7(a-d) is the graph of impedance and frequency of 1K107 series nanocrystalline magnetic core before and after secondary transverse magnetic heat treatment.

It can be seen from Figure 4-7 (a-d) that the relationship curves between the impedance and frequency of the magnetic core after conventional nitrogen protection heat treatment and secondary transverse magnetic heat treatment respectively have intersection points at high frequencies. At 100 kHz, for 1K107C1~1K107D strip cores, the impedances before the second transverse magnetic annealing are 14.60 Ω, 25.32 Ω, 26.73 Ω, 23.75 Ω respectively, and rise to the maximum value of 17.97 after the second transverse magnetic annealing Ω, 27.06 Ω, 28.08 Ω, 23.81 Ω, increased by 23.1%, 6.9%, 5.1%, 0.3%. Compared with the impedance increase of 1K107C1~1K107D strip cores, the secondary transverse magnetic heat treatment has a greater impact on the high frequency impedance of 1K107C1 strip cores, but has no obvious effect on the high frequency impedance of other 1K107 series strip cores.

2.6 Effect of secondary transverse magnetic annealing on the stress resistance performance of the magnetic core

The core samples annealed at the optimal temperature may have better stress resistance. Therefore, 1K107C1,

1K107C2, 1K107C3, and 1K107D nanocrystalline magnetic cores can be used for stress resistance tests after secondary transverse magnetic annealing at 500°C, 420°C, 440°C, and 420°C respectively.

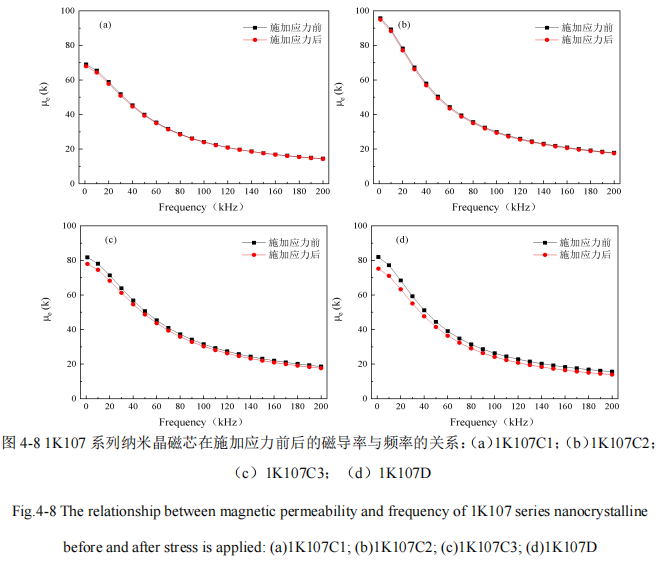

Figure 4-8 (a-d) shows the stress resistance performance parameters of the magnetic core after the heat treatment at the optimum annealing temperature for the second transverse magnetic field. The low frequency (1 kHz) effective permeability of 1K107C1, 1K107C2, 1K107C3, 1K107D nanocrystalline cores before stress is 69.0k, 95.7k, 81.8k, 82.0k; The magnetic permeability is 67.9k, 94.9k, 71.9k, 75.2k respectively, and the change range before and after stress is 1.6%, 0.8%,

12.1%, 8.3%. It can be seen that the 1K107C1 and 1K107C2 nanocrystalline magnetic cores have good stress resistance at low frequencies after the secondary transverse magnetic annealing at 500 ℃ and 420 ℃, respectively.

The high-frequency (100 kHz) effective permeability of 1K107C1, 1K107C2, 1K107C3, and 1K107D nanocrystalline cores before stress is 24.2k, 29.9k, 31.5k, and 26.3k; ) The effective magnetic permeability is 23.9k, 29.4k, 30.2k, 24.2k, respectively, and the change range before and after stress is 1.2%, 1.7%, 4.1%, 8.0%. Therefore, the 1K107C1, 1K107C2 and 1K107C3 nanocrystalline magnetic cores have good stress resistance at high frequencies after undergoing secondary transverse magnetic annealing at 500 °C, 420 °C, and 440 °C, respectively. From the above data analysis, it can be known that the 1K107 series nanocrystalline magnetic core has good stress resistance performance after the secondary transverse magnetic annealing, because the magnetic domain relaxation will occur in the sample treated by the magnetic field, and the magnetization mechanism is based on the magnetic domain rotation. Mainly, stress mainly affects the movement of magnetic domain walls.

3. Comparison of magnetic properties of 1K107C1 core after each annealing process

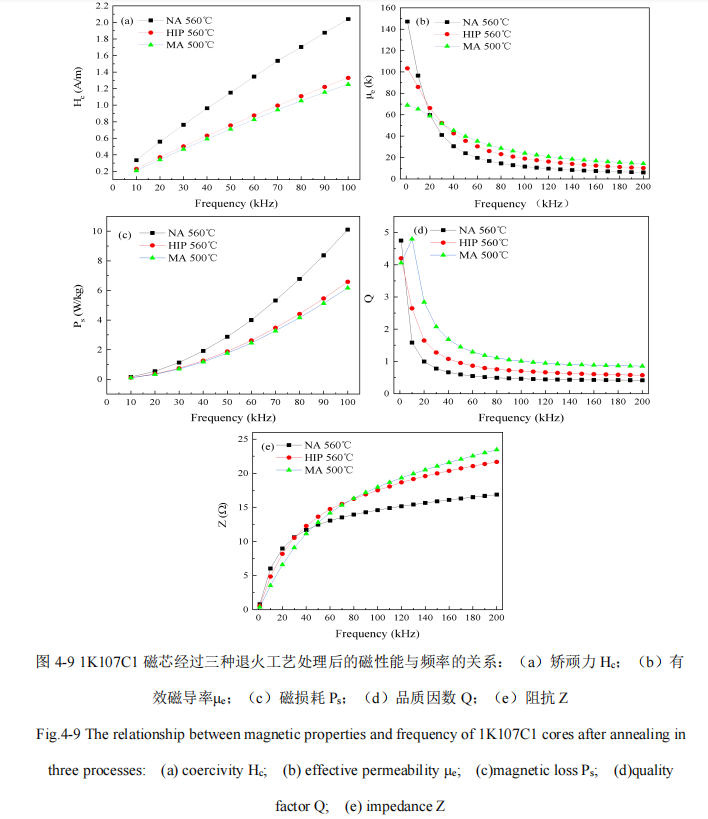

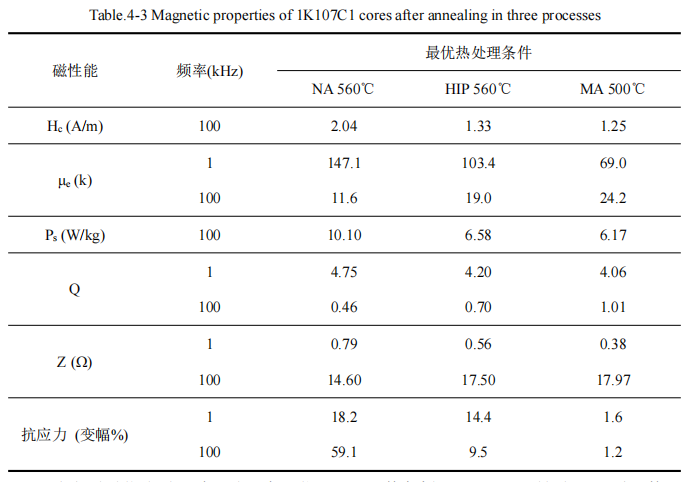

Figure 4-9 (a-e) shows the frequency variation curves of several magnetic properties of the 1K107C1 core after conventional nitrogen heat treatment (NA), hot isostatic pressing (HIP) and secondary transverse magnetic heat treatment (MA), and Table 4- 3 shows the magnetic performance data of the 1K107C1 magnetic core after three annealing processes respectively. Combined with Figure 4-9(a) and Table 4-3, it can be seen that after the 1K107C1 magnetic core has been treated by three annealing processes, the relationship between its high-frequency (100 kHz) coercive force is 2.04A/m(NA)>1.33 A /m(HIP)>1.25 A/m(MA), and the secondary transverse magnetic heat treatment process significantly reduces the high-frequency (100 kHz) coercive force of the 1K107C1 core. Hot isostatic pressing applied a pressure of 20 MPa to the 1K107C1 magnetic core to release the stress of the magnetic core and reduce the pinning of the magnetic domain by stress; while the secondary transverse magnetic heat treatment can not only eliminate the internal stress, but also refine the magnetic domain, so that the magnetic domain is subjected to Pinning can be less.

From Figure 4-9(b) and Table 4-3, it can be found that after the 1K107C1 magnetic core has been treated by three annealing processes, the relationship between its high-frequency (100 kHz) effective permeability is 11.6k(NA)<19.0k (HIP)<24.2k(MA), the comparison shows that the 1K107C1 core has the highest high-frequency (100 kHz) effective permeability after the second transverse magnetic heat treatment. After the 1K107C1 magnetic core undergoes conventional nitrogen heat treatment, due to the uneven arrangement of the magnetic domains inside the magnetic core, its magnetization mechanism is mainly based on the movement of the magnetic domain wall, and some stress remains; after hot isostatic pressing, its magnetization mechanism is also based on The magnetic domain wall moves mainly, and due to the existence of high pressure, a part of the residual stress may be eliminated; after the second transverse magnetic treatment, the magnetic domain tends to be uniformly distributed under the action of the magnetic field, and the magnetization mechanism is dominated by the magnetic domain rotation. . Combining formulas (1.5), (1.6), and (3.7), at the same frequency, the shorter the relaxation time, the higher the magnetic permeability; other conditions are the same, the smaller the internal stress, the larger the magnetic permeability. This shows that the 1K107C1 core may have shorter relaxation time and smaller internal stress after secondary transverse magnetic treatment.

After this type of magnetic core has been treated by three annealing processes, the relationship between its high-frequency (100 kHz) magnetic loss, quality factor, and rent resistance is 10.10 W/kg (NA) > 6.58 W/kg (HIP) > 6.17 W/ kg(MA), 0.46(NA)<0.70(HIP)<1.01(MA), 14.60 Ω(NA)<17.50 Ω(HIP)<17.97 Ω(MA) It has the lowest high frequency (100 kHz) magnetic loss, quality factor and impedance, as shown in Fig. 4-9(c-e). The less the core is affected by stress, the higher the stability of its magnetic properties. After the 1K107C1 magnetic core has been treated by three annealing processes, its stress resistance performance is shown in Table 4-3. Comparing the effects of various heat treatment processes on the stress resistance performance of 1K107C1 magnetic cores, the order of their effects from best to worst is MA, HIP, NA. Comprehensive analysis of high-frequency magnetic properties shows that the optimal heat treatment process for 1K107C1 magnetic core is secondary transverse magnetic heat treatment, followed by hot isostatic pressing, and the worst process effect is conventional nitrogen heat treatment.

4. Summary

This chapter explores the influence of secondary transverse magnetic heat treatment on the soft magnetic properties of 1K107 series nanocrystalline magnetic cores, obtains the best soft magnetic properties of 1K107 series magnetic cores after magnetic field annealing, and draws the following conclusions:

1) The permeability change of 1K107 series nanocrystalline magnetic cores before and after the second transverse magnetic annealing shows that the low frequency decreases and the high frequency increases. 1K107C1, 1K107C2, 1K107C3, 1K107D nanocrystalline magnetic cores undergo secondary transverse magnetic annealing at 500°C, 420°C, 440°C, and 420°C respectively, and their low-frequency (1 kHz) effective permeability are 69.0k, 95.7k, 81.8k, 75.7k, respectively decreased by 53.1%, 21.8%, 25.2%, and 38.0% compared with before the second transverse magnetic annealing; their highest high-frequency (100 kHz) effective permeability was 24.2k, 29.9 k, 31.5k, and 26.3k, respectively increased by 108.7%, 42.8%, 30.1%, and 32.4% compared with before the second transverse magnetic annealing; among them, the 1K107C3 strip core has the highest value after the second transverse magnetic annealing at 440 ℃ High frequency (100 kHz) effective permeability.

2) The magnetic loss of 1K107 series nanocrystalline magnetic cores will be reduced after the second transverse magnetic annealing. 1K107C1, 1K107C2, 1K107C3, and 1K107D strip cores were annealed at 500 ℃, 420 ℃, 440 ℃, and 420 ℃, respectively. 4.90 W/kg, 5.77 W/kg, respectively decreased by 38.9%, 18.1%, 3.5%, and 17.1% compared with those before magnetic field heat treatment.

3) 1K107C1, 1K107C2, 1K107C3, and 1K107D nanocrystalline magnetic cores have good stress resistance performance at low and high frequencies after secondary transverse magnetic annealing, and their effective permeability varies from 0.8 to 12.1 before and after stress is applied. %.

4) For low-frequency magnetic properties, the best annealing process for 1K107C1 core is conventional nitrogen heat treatment, followed by hot isostatic pressing, and the worst process effect is secondary transverse magnetic heat treatment; the highest low frequency (1 kHz) of 1K107C1 core is effective The magnetic permeability is 147.1k. For high-frequency magnetic properties, the best annealing process for 1K107C1 core is secondary transverse magnetic heat treatment, followed by hot isostatic pressing, and the worst process effect is conventional nitrogen heat treatment; the highest high-frequency (100kHz) effective magnetic The conductivity is 24.2k.

In this paper, the soft magnetic properties of 1K107 series amorphous and nanocrystalline alloys were improved by conventional nitrogen protection heat treatment, hot isostatic pressing and magnetic field heat treatment at different annealing temperatures. The soft magnetic properties such as the crystal structure of the iron-based amorphous strip, the inductance L of the magnetic core and the magnetic loss Ps were measured by X-ray diffractometer, precision magnetic component tester and soft magnetic AC equipment. The main conclusions are as follows:

(1) The effective permeability of the 1K107 series nanocrystalline magnetic core after conventional nitrogen protection heat treatment decreases rapidly with the increase of the frequency of the AC signal. 1K107C1, 1K107C2, 1K107C3, 1K107D and 1K107J strip cores have the highest low-frequency (1 kHz) effective permeability after annealing at 560 ℃, 540 ℃, 540 ℃, 540 ℃ and 550 ℃ respectively, which are 147.1k, 152.2k, 139.3k, 152.6k, 123.6k; after annealing at 560 ℃, 550 ℃, 550 ℃, 550 ℃, 560 ℃ respectively, they have the highest high-frequency (100 kHz) effective permeability, 11.5k respectively , 20.9k, 24.2k, 19.8k, 16.1k. Comparing the five kinds of strips, the 1K107D strip core has the highest low-frequency (1 kHz) effective permeability after annealing at 540 °C, and the 1K107C3 strip core has the highest high-frequency (100 kHz) effective permeability after annealing at 550 °C. Conductivity.

(2) The magnetic loss of the 1K107 series nanocrystalline magnetic core after conventional nitrogen protection heat treatment increases with the increase of the frequency of the AC signal. The 1K107C1, 1K107C2, 1K107C3, 1K107D and 1K107J strip cores have the lowest high frequency (100 kHz) magnetic losses of 9.08 W/kg after annealing at 570 °C, 550 °C, 550 °C, 550 °C and 560 °C, respectively , 6.20 W/kg, 6.10 W/kg, 6.96 W/kg, 7.83 W/kg (Bm=0.1 T). Among the five tapes, the 1K107C3 tape core annealed at 550 °C has the lowest high frequency (100 kHz) magnetic loss.

(3) After the 1K107C1 and 1K107J strip cores are subjected to conventional nitrogen protection heat treatment at 560 ℃, their low-frequency (1kHz) effective magnetic permeability is 147.1k and 120.2k respectively, and their high-frequency (100 kHz) effective magnetic permeability is 11.6 k,

16.1k. However, after hot isostatic pressing at 560 ℃, the effective permeability at low frequency (1 kHz) was 103.4k and 131.7k, respectively, which decreased by 29.7% and increased by 9.6% compared with the former; ) The effective magnetic permeability is 19.0k and 13.4k respectively, which are respectively increased by 63.8% and decreased by 16.8% compared with the former. The hot isostatic pressing process can improve the high-frequency soft magnetic properties of 1K107C1.

(4) Among the magnetic core samples subjected to conventional nitrogen protection heat treatment, 1K107C2 and 1K107C3 nanocrystals have good stress resistance at low frequencies, and 1K107C3 and 1K107D strip cores have good performance at high frequencies after conventional nitrogen protection heat treatment at 550 °C. anti-stress properties. 1K107C1, 1K107C2, 1K107C3, and 1K107D nanocrystalline magnetic cores have good stress resistance at low and high frequencies after secondary transverse magnetic annealing, and their effective permeability varies from 0.8 to 12.1% before and after stress is applied. .

(5) The low-frequency (1 kHz) effective permeability of the 1K107C1 and 1K107J nanocrystalline magnetic cores after 560 ℃ hot isostatic pressing before and after stress were 18.2 % and 69.7 % respectively. (100 kHz) effective permeability change ranges are 9.5 % and 27.6 % respectively, and the 1K107C1 nanocrystalline core has better stress resistance performance at high frequencies.

(6) After the 1K107 series nanocrystalline magnetic core undergoes secondary transverse magnetic annealing, its low-frequency effective permeability decreases and its high-frequency effective permeability increases. 1K107C1, 1K107C2, 1K107C3, 1K107D nanocrystalline magnetic cores undergo secondary transverse magnetic annealing at 500°C, 420°C, 440°C, and 420°C respectively, and their low-frequency (1 kHz) effective permeability are 69.0k, 95.7k, 81.8k, 75.7k, respectively decreased by 53.1%, 21.8%, 25.2%, and 38.0% compared with before the second transverse magnetic annealing; their highest high-frequency (100 kHz) effective permeability was 24.2k, 29.9 k, 31.5k, and 26.3k, respectively increased by 108.7%, 42.8%, 30.1%, and 32.4% compared with before the second transverse magnetic annealing; among them, the 1K107C3 strip core has the highest value after the second transverse magnetic annealing at 440 ℃ High frequency (100 kHz) effective permeability.

(7) The magnetic loss of 1K107 series nanocrystalline magnetic cores will be reduced after the second transverse magnetic annealing compared with that before annealing. The 1K107C1, 1K107C2, 1K107C3, 1K107D strip cores have the lowest high-frequency (100 kHz) magnetic losses, 6.17 W/kg, 5.08 W/kg, 4.90 W/kg, 5.77 W/kg (Bm=0.1 T), respectively decreased by 38.9%, 18.1%, 3.5%, and 17.1% compared with before the second transverse magnetic annealing; among them, the 1K107C3 nanocrystalline magnetic core It has the lowest high-frequency (100 kHz) magnetic loss after secondary transverse magnetic annealing at 440 ℃.

Vacuum Drying Process For 220KV Current Transformer Trolley Annealing Furnaces For Pressure Vessel Components QT40-10 Ductile Iron Heat Treatment Process

Contact us

Your email address will not be published. Required fields are marked *