Vacuum Pressure Impregnating Process For Motor Coil

Introduction

Current motor armature varnished process for vacuum immersed,the workpiece is placing in a vacuum container, through the workpiece vacuum is excluded from the water and other volatiles in the gap between winding with insulating paint again after filling and curing process, applicable to all kinds of large gap between winding, rotor armature insulated enclosed, corresponding to the tank is full of high rate of winding, there is phenomenon of incomplete impregnated, armature poorly sealing varnished, whether slot insulation layer insulation, and insulation and the outer layer of the tie line and the power lead, has a large number of stoma, insulating materials in more than 65% relative humidity of the air, suck tide began to rapidly.This moisture absorption quickly reduces the surface resistivity and resistivity.As a result, the insulation drop of the armature winding to the shaft affects the insulation performance of the motor.Finally, it is shown that the insulation layer of enameled wire has poor protection effect and unstable insulation performance, which makes it difficult to meet the severe working environment requirements of military motors.

To solve the problem of insulation resistance decreased after the armature varnished, is to make it easier for liquid paint to fill gaps, improve the effect of vacuum degree can improve the varnished, but vacuum environment to a certain temperature under the condition of a kind of liquid dipping paint, when the vacuity is lower than a – absolute pressure values, i.e. to achieve a vacuum – the corresponding critical, “leads to a large number of bubbles and liquid surface in the impregnating varnish liquid production of large amounts of the mist, namely” foam “and” atomization “phenomenon.”Foam” causes a large number of holes in the paint solution, will hinder infiltration.”Atomization” causes a large amount of solvent or diluent to escape, which will affect the curing.Therefore, the only way to improve the painting quality of the generator armature is to change the painting process.

VPI vacuum pressure varnished with vacuum leaching paint process is different, then fill the gap between winding insulation varnish, pressure container, it can make the insulating paint permeate and full of insulation lining structure, has good insulation performance, lowering the temperature rise of the generator, increasing the mechanical strength and improve the moisture ability of the armature, prolonging the service life of products.

In order to optimize the vacuum pressure coating effect of precision motor, it is necessary to optimize the process parameter equipment and verify the effect through experiments, so as to improve the impregnation quality and make the motor meet the requirements of high temperature and high humidity working environment.

1. Function of motor armature immersion paint

1.1 principle of vacuum pressure impregnation

The workpiece cooling after pre bake moisture, placed in a vacuum environment, remove the inside of the coil air and volatile, depending on the paint in the vacuum liquid gravity and coil capillary action and the use of dry compressed air or inert gas to remove after vacuum impregnation liquid paint a certain pressure, rapid infiltration and populate the lacquer liquid junction insulation E = : E t structure inside.So that the wire and the core form a whole.

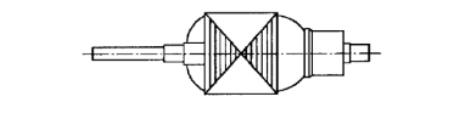

The appearance of the armature is shown in figure 1.

1.2 Purpose of vacuum pressure impregnation

VPI vacuum pressure impregnation with vacuum impregnation process is different, then fill the gap between winding insulation varnish, pressure container, it can make the insulating paint permeate and full of insulation lining structure, has good insulation performance, lowering the temperature rise of the generator, increasing the mechanical strength and improve the moisture ability of the armature, prolonging the service life of products.VPI process flow :pre-drying dehumidification – laoding to tank→ exhaust →vacuum impregnation process → pressure impregnation → pressure discharge paint → pressure relief drip paint →tank → curing and drying → out of the tank. Therefore, in order to improve the insulation performance of the generator armature after painting, it is necessary to change the current vacuum immersion to vacuum pressure painting.Its main objectives are as follows:

The gap and bubble in the coil are eliminated to achieve the one-body property of the armature, and the internal micro-vibration is avoided, thus reducing the damage of friction to the armature insulation structure.The elimination of voids and bubbles can effectively reduce partial discharge and avoid breakdown failure after long-term operation.The full filling of insulating paint is conducive to the reliability of insulation and the derivation of heat, ensuring the low temperature rise of armature and the reliability of insulation.

1.3 Quality inspection of armature after vacuum pressure painting

After the completion of vacuum pressure impregnation, it is necessary to check the following contents: appearance quality (curing state of insulating paint, whether there are bubbles or holes on the surface), thermal insulation resistance, cold insulation resistance, voltage resistance, etc

1) Appearance requirements during and after painting.The appearance of immersion paint after curing should be checked, the paint film should be flat and smooth, no paint tumor, caking and other phenomena.

2) Check the thermal and cold insulation resistance and voltage resistance of the armature after painting.

The thermal insulation resistance shall be no less than 100 MQ for the normal armature after the immersion curing;Cold insulation resistance is no less than 500 Mn.3) moisture and heat test of lacquer immersion armature.

The hot and cold insulation resistance of the test parts which are qualified after being dipped in paint shall be tested by alternating wet-heat test, and the hot and cold insulation resistance during the test and after the test.

Automobile Piston Ring Nitriding Process Introduction And Classification Of Annealing Process The Role Of Quenching Medium In Controlling Heat Treatment Deformation Of Parts

Contact us

Your email address will not be published. Required fields are marked *