Current Stress Annealing of Iron-based Nanocrystalline Alloys

The Fe73.5Cu1Nb3Si13.5B9 amorphous alloy was treated by DC Joule heating with stress and without stress annealing, and the dynamic hysteresis loop, Mössbauer spectrum and longitudinally driven giant magnetoimpedance effect were studied. The results show that the Fe73.5Cu1Nb3Si 13.5B9 amorphous alloy crystallizes when the current density is greater than 4.11×107A/m2 and produces a transverse magnetic structure under stress annealing. Under certain conditions, the induced anisotropy increases with the increase of the current density. This is closely related to the number of α-FeSi nano-grains in the alloy.

The iron-based nanocrystalline alloy, discovered and named Fine met in 1988, is favored by scientists and manufacturers all over the world because of its excellent comprehensive soft magnetic properties. In addition to the traditional isothermal annealing method for crystallization of iron-based amorphous materials, electric current heating is also commonly used. The magnetic properties of Fe-based nanocrystalline materials prepared by direct current, alternating current or pulse current heating are comparable to those of conventional annealing, and have the advantages of short processing time, high initial magnetic permeability, and improved material brittleness. It is generally believed that current annealing technology mainly uses Joule heat of current to rapidly reach a higher temperature in materials than conventional annealing to activate structural transformation in a short time. In 1992, Mohri et al. first discovered the giant magnetoresistance effect in Co-based amorphous wire, and then people soon observed it in Fe-based nanocrystalline thin ribbons, films and wires that also have high magnetic permeability and low magnetostriction coefficient. to the magnetoresistance effect. Inspired by the large giant magneto-impedance effect observed in Co-based amorphous materials with transverse magnetic structure, people can also obtain Fe-based nanocrystalline materials with transverse magnetic structure by using transverse magnetic field annealing and tensile stress annealing and observe that Larger giant magneto-impedance effect, but the magnetostriction coefficient λs of Fe-based microcrystalline materials is positive The mechanism of obtaining transverse magnetic structure under the action of tensile stress is still debated. In this paper, nanocrystalline materials with transverse magnetic structure were prepared by current stress annealing, and the reasons for the induced magnetic anisotropy were preliminarily discussed by means of dynamic hysteresis loops and M¨Ossbauer spectroscopy.

1. Experiment

Amorphous Fe73.5Cu1Nb3Si 13.5B9 thin strips were made by single-roll rapid quenching. Width 0.79mmThickness 20μmIntercept 13.5cm long sampleCarry out DC current annealing for 5min under nitrogen protectionCurrent density j at 3 .80×107A/m2 to 4.75×107A/m2 and the stress applied to the sample is fixed at σ0=44.0MPa and keep the stress and nitrogen protection until the sample cools to room temperature. The dynamic hysteresis loop (1kHz) of the sample was measured by the compensating coil method. Room temperature 57Fe Mössbauer spectrum measurement was carried out on Canberra’s Series 40MCA spectrometer 57Co(Pd) with a radioactive source of 7.4×108Bq The velocity was calibrated by room temperature α-Fe spectrum. The giant magnetoimpedance effect was measured on a self-made computer-controlled impedance analyzer.

2. Results and Discussion

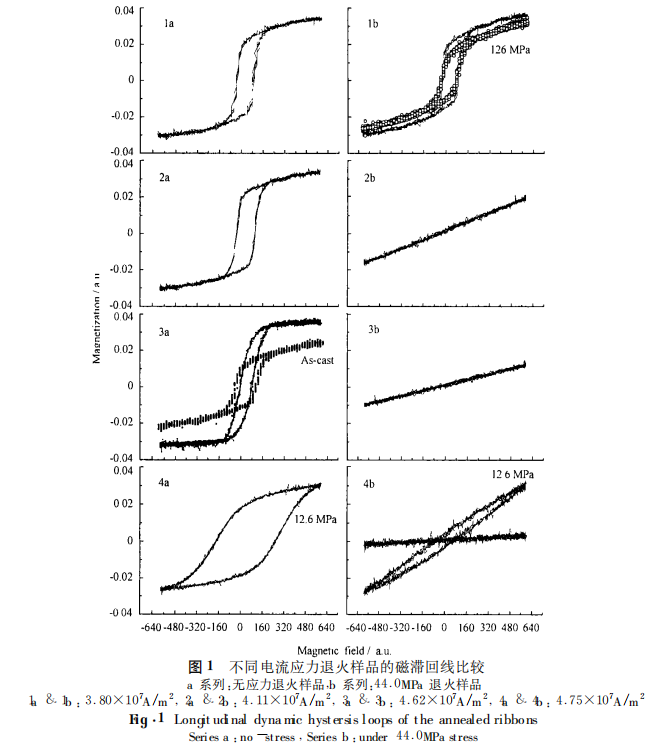

Figure 1 is the hysteresis loops of stress and non-stress annealed samples under different current densities. The two graphs in each row are samples annealed at the same current density where the 4.62×107A/m2 annealed sample represents the current density range from 4.30×107A/m2 to 4.62×107A/m2 in this range There is no significant difference in the hysteresis loops of internally annealed samples.

First examine the hysteresis loops of the non-stress current annealed samples amorphous samples (As-cast) in the series a on the left of Figure 1 and put them in Figure 3a for comparison. It is not difficult to find that the soft magnetic properties of samples are closely related to the annealing current. When annealing with a smaller current the saturation magnetization of the sample increases and the coercive force Hc slightly improves with the increase of the current density the saturation magnetization continues to increase the coercive force also greatly decreases the soft magnetic properties are significantly improved. When annealing with a larger current, the soft magnetic properties of the material become worse and the coercive force increases sharply.

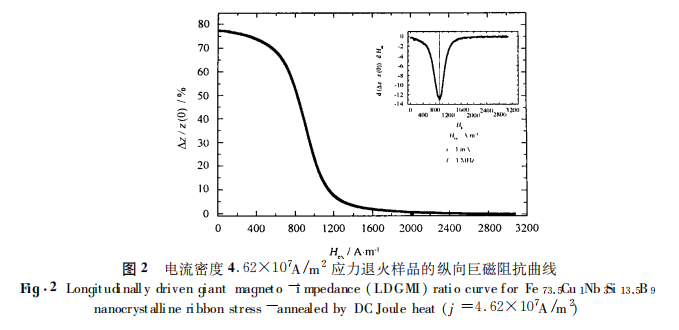

The series b on the right side of Figure 1 shows the hysteresis loops of samples annealed with different currents under the stress of 44.0 MPa. We found that whether transverse magnetic anisotropy can be produced in the samples is closely related to the magnitude of the current density. Under the annealing condition of 3.80×107A/m2, there is no significant difference between the 44.0MPa stress annealed sample and the unstressed annealed sample. Even if the stress is increased to 126MPa, the saturation magnetization is only reduced. There is still no obvious difference. The transverse magnetic structure is formed. When the current density increases to 4.11×107A/m2, the hysteresis loop of the 44.0MPa stress annealed sample shows a better linearity. This is a typical magnetization process dominated by magnetic moment rotation. It shows that the sample has Good transverse magnetic structure. With the further increase of the annealing current, it can be seen that the hysteresis loop directly reverses to the H axis, indicating that the induced anisotropy also increases. However, in the sample annealed at 44.0MPa under 4.75×107A/m2, the lateral anisotropy is so large that it is difficult to achieve saturation in the magnetic field range of our experiment. Under the same current density, the application A small stress of 12.6MPa annealing still has obvious transverse magnetic structure. Fig. 2 is the longitudinal drive giant magnetoimpedance effect curve of the 4.62×107A/m2 stress annealed sample. It shows the impedance curve of the typical “plateau” mode of the sample with transverse magnetic structure under the longitudinal drive field[11]. The magnetic moment of the sample is mostly aligned along the direction perpendicular to the belt axis so in the longitudinal drive mode the magnetic moment rotational magnetization is dominant. When the external field changes within a range much smaller than the anisotropy field Hk, the material is basically in a state of transverse magnetic saturation, and the magnetization state will not change greatly, so the impedance changes little; when the external field is much larger than the anisotropy When the field Hk changes within the range, the material is basically in the longitudinal magnetic saturation state, and there will be no large impedance change; only when the external field changes near Hk, the impedance will drop sharply. The external field corresponding to the peak value of the differential curve of the impedance against the external field shown in the inset of the figure is the anisotropy field Hk of the material.

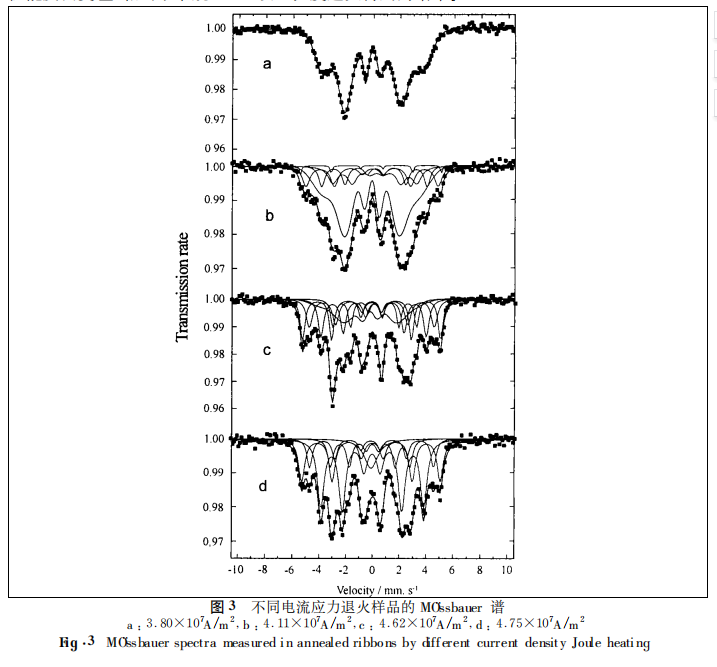

In order to study the mechanism of transverse magnetic structure produced by current stress annealing, we measured the M¨Ossbauer spectrum of the above samples Figure 3 shows the M¨Ossbauer spectrum of the amorphous Fe73.5Cu1Nb3Si13.5B9 thin strips after heating and annealing with different current densities When the current density is 3.80×107A/m2 The spectral line is a typical amorphous M¨Ossbauer spectrum It can be seen that the current density is too smallAmorphous without crystallizationAs the current density increasesto 4.11×107A /m2 Amorphous ribbons begin to crystallize The proportion of α-Fe(Si) grains formed by crystallization increases with the increase of current density Mu spectrum is fitted with 5 sets of subspectral linesFour sets of six lines The spectrum corresponds to the DO3 structure of the nanocrystalline phase α-Fe(Si) The other is the broadened peak of the amorphous residual phase Fitting the annealed sample at 4.62×107A/m2 shows that the volume ratio of the residual amorphous phase in the sample at this time It is 38% which is similar to the best soft magnetic properties of the material when the volume fraction of amorphous phase is 30-40% in the sample annealed at 540°C by conventional annealing and when the current density is 4.75×107A/m2, the amorphous phase in the sample is Complete crystallization and Fe2B, Fe3B generation Mu spectrum using four sets of six-line sub-spectrum and a set of single peak to fit.

Combined with the dynamic hysteresis loop and M¨Ossbauer spectrum, it can be seen that when annealed with a small currentthe sample is amorphized or has little crystallizationthe soft magnetic properties of the sample are not significantly improvedwith the increase of the heating current densitythe sample has The best nano-grain volume ratio and appropriate grain sizeThe soft magnetic properties are the bestThis is similar to the results obtained by conventional 540°C annealingWhen the current density increases to 4.75×107A/m2In the sample Hard magnetic phases such as Fe2B and Fe3B appear At the same time, the grain grows No longer meets the exchange coupling conditions Soft magnetic properties become worse It is equivalent to the result obtained by conventional annealing at a temperature above 650°C.

3. Conclusion

In summary, we get the following conclusions:

(1) Fe-based nanocrystalline materials with transverse magnetic structure were obtained by tensile stress annealing method under appropriate current density conditions.

(2) The annealing current density has a great influence on the formation of induced anisotropy. Under the same stress, the greater the current, the easier it is to produce anisotropy; and under a certain current threshold, it is difficult to induce anisotropy even if the stress is increased, and for high current annealing, only a small stress is required to produce Induced anisotropy exists.

(3) In Fe-based nanocrystalline materials, the process of inducing transverse anisotropy through longitudinal tensile stress annealing is closely related to the α-FeSi grains in the material. If the material is not crystallized, it will be very Difficulty producing lateral anisotropy.

(4) Under certain conditions, the induced anisotropy increases with the increase of the current density. This is closely related to the amount of α-FeSi nano-grains in the alloy.

Effect of Annealing Process on Soft Magnetic Properties of FeSiBCuNb Alloys Trolley Annealing Furnaces For Pressure Vessel Components Analysis Of Common Problems In Carburizing And Nitriding

Contact us

Your email address will not be published. Required fields are marked *