Improvement of Cementation Process for 20Mn2 Automobile Snow Chains

The snow chain is a kind of annular chain installed on the tire of the car. It is mainly used for anti-skid driving in snowy weather to ensure safe driving. It is an essential tool for driving in the alpine zone in winter. Therefore, the snow chain is required to be wear-resistant and not broken. That is, the chain must have good wear resistance and toughness. With the enhancement of people’s awareness of security. The use of automobile snow chains is becoming more and more extensive.

20Mn2 steel has good cementation and hardening properties, especially excellent wear resistance. Therefore, in addition to being used to manufacture lifting chains, it is also widely used by factories to manufacture snow chains for heavy-duty trucks.

The following is an example of a heavy duty snow chain. The inner space of the single ring is 12mm × 42mm, and the wire diameter is 7mm. Technical requirements: the carburized layer thickness is 0.25~0.35mm, the surface hardness is >54HRC, the core hardness is >40HRC, and the tapping test value is not less than 30KN.

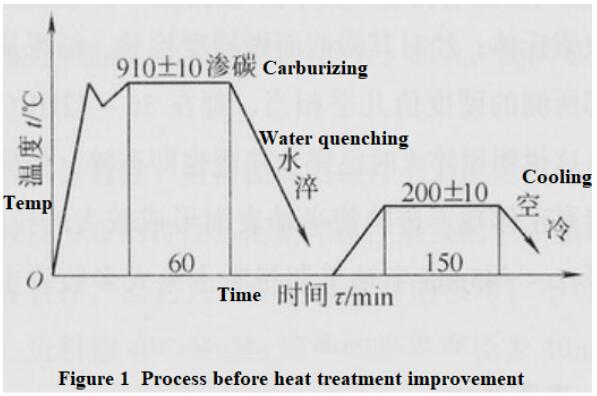

Most factories generally use the heat treatment process shown in Figure 1.

1. Process comparison before and after improvement

The advantages of the above process are: to the warm charging furnace, directly water quenching after heat preservation and cementation, the production rhythm is fast, and the cycle is short, which is conducive to improving the production labor rate. The disadvantage is: although the thickness of the seepage layer, the hardness of the surface and the core all meet the requirements, it is difficult to reach 30kN in the tap-pull test. occur, which will adversely affect the enterprise.

Obviously, the heat treatment process shown in Figure 1 focuses on ensuring surface hardness and wear resistance, while neglecting the strength and toughness of the core. Therefore, the heat treatment process must be improved.

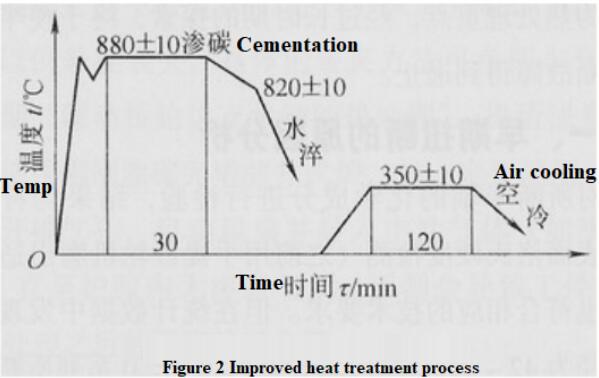

Compared with the process in Figure 1, the improved heat treatment process (see Figure 2) has the following characteristics:

Reducing the cementation temperature and shortening the cementation time is beneficial to prevent the grain growth and improve the mechanical properties.

(2) Reduce the quenching temperature. After cementation for 30 minutes, cut off the power supply to cool down. In this stage, kerosene is still dripped in a certain dose to ensure no oxidation and decarburization during cooling. At the same time, it can also play a diffusion role and expand the depth of the cementation layer (the cementation time of this process is relatively short: 30 minutes). ); reducing the quenching temperature can also reduce the amount of retained austenite, thereby reducing brittleness.

(3) Increase the tempering temperature. Change the low temperature tempering to the medium temperature tempering to improve the toughness of the chain.

(4) The overall performance is significantly improved. Except for the thickness of the infiltrating layer and the surface hardness are the same as the original process, the hardness of the core is on the lower limit (in the range of 40-44HRC), and the tapping and pulling test value can reach more than 30kN.

(5) Production efficiency has not decreased. The actual measurement shows that the two process cycles are basically the same, and there is no obvious impact on the production efficiency.

2. Conclusion

After the improvement of the heat treatment process, it not only ensures that the chain has high wear resistance, but also fundamentally solves the problem of chain breakage in use.

Learn More :Heat Treatment Process Control Of Magnetic Properties Of FeCuNbSiB Nanocrystals Controlled Atmosphere Pit Type Carburizing Production Line Equipment QPQ Salt Bath Liquid Nitriding Surface Technology Inspection Procedure

Contact us

Your email address will not be published. Required fields are marked *