Study on Soft Magnetic Properties of Iron-Based Amorphous/Nanocrystalline Alloys Under Magnetic Field/Stress Heat Treatment

Iron-based amorphous/nanocrystalline alloys have attracted the attention of researchers because of their excellent properties such as high saturation magnetic induction Bs, low coercive force Hc, high magnetic permeability μe, and low loss P. After decades of development, the comprehensive soft magnetic properties of iron-based amorphous/nanocrystalline alloys have been greatly improved, and have become an important branch of soft magnetic materials. However, compared with traditional silicon steel, the relatively low saturation magnetic induction Bs of iron-based amorphous/nanocrystalline alloys hinders its further development. In this context, this paper uses the method of magnetic field/stress heat treatment, combined with the addition of an appropriate amount of Co element, to further increase the magnetic induction Bs of the alloy without destroying the soft magnetic properties of the iron-based amorphous/nanocrystalline.

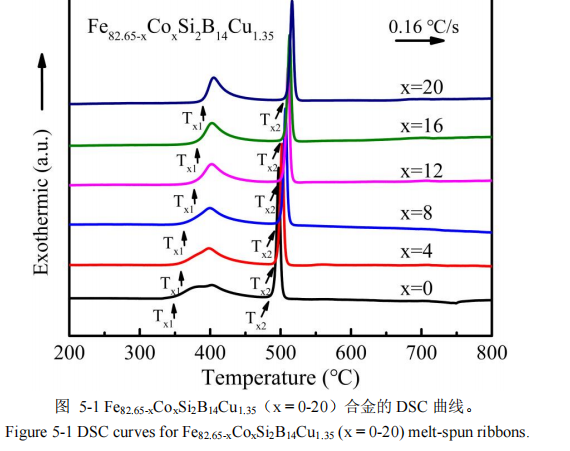

First, based on the FeSiBCu alloy system, Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) amorphous strips were prepared by adding Co elements, and the soft magnetic properties of the amorphous strip samples were successfully improved by magnetic field annealing. Energy and saturation magnetic induction Bs, making the maximum saturation magnetic induction Bs up to 1.86 T. Thermodynamic tests on amorphous samples found that the addition of Co element can not only improve the thermodynamic stability of the alloy but also increase the Curie temperature TC of the alloy. Through the observation of the magnetic domain of the sample, it is found that the magnetic field annealing can well adjust the internal magnetic domain structure of the sample, eliminate the magnetic anisotropy, reduce the pinning effect, and thus effectively improve the soft magnetic properties. Through the transmission electron microscope and DSC curve of the sample, it is found that the magnetic field annealing can promote the precipitation of α-Fe grains to a certain extent, improve the order degree of the alloy, and further increase the saturation magnetic induction Bs of the alloy.

On the basis of the above experimental results, Fe82.65-xCoxSi2B9P5Cu1.35 (x = 0-20) amorphous strips were prepared by adding an appropriate amount of P element, and the soft magnetic properties of iron-cobalt-based nanocrystals in this system were studied in combination with magnetic field annealing with microstructural changes. It is found that magnetic field annealing can effectively improve the magnetic permeability of the samples containing no Co element or low Co element. The soft magnetic properties of samples containing high Co elements are significantly different at different annealing temperatures. It was found by transmission electron microscopy that the different grain sizes lead to different sensitivities of the samples to the applied magnetic field. Because the addition of Co element reduces the ferromagnetic exchange length Lex of the sample, the low annealing temperature leads to a large grain size, which makes it difficult for the sample to meet the necessary conditions for an effective stochastic anisotropy model.

Finally, this paper still takes the Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) amorphous ribbon as the experimental research object, and successfully improved the coercive force Hc of the amorphous ribbon sample by tensile stress annealing, Co element content When it is higher, the effect is more pronounced. It is also found that when the tensile stress is small, the coercive force Hc of the sample is significantly improved, and as the tensile stress continues to increase, the effect tends to be gentle. With the help of synchrotron radiation experiments, it was found that the tensile stress can change the atomic distance of the strip sample, and the analysis of the thermal expansion behavior of the tensile stress sample shows that the tensile stress sample has a higher thermal expansion coefficient and rise rate than the ordinary annealed sample, which may be Because tensile stress annealing effectively reduces the magnetostriction coefficient of the sample, and the ordinary annealed sample has an “Invar effect” due to its large magnetostriction coefficient in the thermal expansion process, resulting in a low thermal expansion coefficient and a slow rise rate.

1. Overview of the development of amorphous/nanocrystalline magnetic field/stress heat treatment

While researchers focused on exploring the composition of amorphous/nanocrystalline soft magnetic materials, they also improved their processes. In addition to the conventional isothermal annealing process, other processes such as rapid annealing, step annealing, magnetic field annealing and stress annealing are also being further explored by researchers. This paper mainly introduces two magnetic field/stress heat treatment methods: magnetic field annealing and stress annealing.

2. Overview of heat treatment of amorphous/nanocrystalline magnetic field

The shape of the hysteresis loop of the alloy after magnetic field annealing will change. In order to obtain better soft magnetic properties, more and more scientific researchers have invested in the magnetic field annealing process. Suzuki and Ito conducted a systematic study on FeCoZrB and FeNbB systems by using rotating magnetic field annealing [31-35]. In the study of FeCoZrB system, it is found that rotating magnetic field annealing can suppress the induced anisotropy produced by annealing, reduce the coercive force, the influence of uniaxial anisotropy on the technical magnetization is weakened, and the influence of magnetocrystalline anisotropy is enhanced. At the same time, the mechanism of nanocrystalline soft magnetic properties was supplemented on the basis of FeNbB system by using rotating magnetic field annealing, and the Herzer model was further improved [17]. The influence of Ku on soft magnetic properties was studied, and it was found that Ku:K1=2:1 When is the critical value, it determines the law between the grain size and the coercive force, and supplements and corrects the D6 law proposed in the Herzer model. Skorvanek et al. used magnetic field annealing to improve the soft magnetic properties of Hitperm-type nanocrystalline systems [36-38]. In FeCoNbB, FeNiNbB and FeCoMoBCu and other systems, he studied the improvement of soft magnetic alloy properties by longitudinal magnetic field annealing and transverse magnetic field annealing, and discussed the influence of Fe/Co ratio on Ku value. Studying the magnetic domain structure, it can be found that in the absence of a magnetic field, the magnetic domain pattern is chaotic, the direction of the domain wall is inconsistent, the width of the magnetic domain is uneven, there are wide and uneven main domains and small and curved sub-domains; the magnetic domain structure after magnetic field treatment Simple, the edge of the magnetic domain is smooth, which explains the reason why the magnetic field annealing improves the soft magnetic properties of nanocrystals. Wang et al. also studied the high-temperature permeability and the influence of magnetic field annealing on process parameters on λs and μi by replacing Fe elements with Co elements on the basis of the Finemet system, and through the magnetic field annealing process [39-40]. It is found that λs and μi are inversely proportional to each other. After normal annealing, λs is higher, but after magnetic field annealing, λs is significantly lower. Marin et al. used magnetic field annealing to study the soft magnetic properties of Co-rich nanocrystals in the Finemet system, and observed a change in the grain size after magnetic field annealing through transmission electron microscopy [41]. Recently, Inoue and his team used magnetic field annealing to prepare amorphous strips with excellent soft magnetic properties, with Bs as high as 1.92 T and coercive force as low as 2 A/m[42-43]. Wang et al. used the FeCoSiBPC system to study the mechanism of magnetic field annealing in amorphous, and found that when a certain amount of Co was added, the Curie temperature of the amorphous substrate would be higher than the first crystallization peak temperature, that is, when TC>TX1 , amorphous strips with excellent soft magnetic properties can be obtained by magnetic field annealing [44]. Therefore, magnetic field annealing can not only be used to study the soft magnetic performance mechanism of amorphous nanocrystals, but also can be used to improve the properties of soft magnetic alloys.

Magnetic field heat treatment, that is, an external magnetic field is applied during the heat treatment of materials. For soft magnetic materials, the effect of magnetic field heat treatment on soft magnetic alloys can be simply regarded as adding a uniaxial magnetic anisotropy to the material, also known as induced anisotropy. Magnetic field heat treatment generally achieves a preferred orientation of the magnetization of a sample by rearranging atoms at a local scale, which is favorable for a given orientation of the magnetization. At an annealing temperature Ta high enough to cause the atoms to move, but not so high that the material is no longer magnetic (Ta < Tc), some pairs of atoms orient themselves relative to the magnetization direction so that their magnetic anisotropy can be minimized. Once the temperature is lowered to a temperature at which diffusion no longer takes place, the frozen pairs of atoms are directional ordered enough to override the other anisotropy and retain the magnetization orientation that had been achieved during annealing if the magnetic field is removed. Combining magnetic field annealing with composition exploration of soft magnetic alloy systems to obtain excellent soft magnetic properties and understand the internal mechanism is worthy of further study.

3. Overview of amorphous/nanocrystalline stress heat treatment

In 1975 and 1980, Egami et al. and Mizoguchi et al. used tensile stress annealing above 200 °C on Fe40Ni40P14B6 amorphous strips to achieve the effect of increasing the remanence ratio and reducing the coercive force[45-46]. Similar optimization of soft magnetic properties also occurs in Fe80P13C7 amorphous alloys [47]. In 1979, Hatta used tensile stress annealing and magnetic field annealing to obtain Fe86B7C7 amorphous strips with high saturation magnetic flux at room temperature and extremely low coercive force, and the effect of stress annealing was more prominent [48]. In 1999, Tejedor et al applied tensile stress annealing treatment to Fe81B13.5Si3.5C2 amorphous strips, resulting in a significant reduction in the surface coercive force. In contrast to magnetic field-induced anisotropy which has an easy axis parallel to the annealing field (with very few exceptions), stress-induced anisotropy has an indeterminate easy axis, either parallel or perpendicular to the tensile stress, which may be why stress annealing plays an important role in optimizing non- The reason why the application and development of soft magnetic properties of crystal alloys is greatly limited [49]. On the other hand, the physical and structural origins of creep-induced magnetic anisotropy have been extensively studied with the aid of stress heat treatment. Nielson proposed that creep-induced anisotropy is composed of anelastic and plastic terms[47], and systematically explored the effects of annealing temperature, time, stress and composition on creep-induced magnetic anisotropy, and obtained the following characteristics: For a given The annealing temperature/time, creep-induced magnetic anisotropy is proportional to the tensile stress applied during the annealing process [50]; when the annealing temperature is increased under constant applied stress, the creep-induced magnetic anisotropy has a maximum value [51]. Most of the research on the physical origin of creep-induced magnetic anisotropy focuses on the composition dependence of creep-induced anisotropy. Hernando proposed a chemical short-range order model based on the FeCoSiB system: the local magnetoelastic coupling of Bernal tetrahedrons composed of specific Fe and Co atoms dominates the macroscopic creep-induced anisotropy[52]; Herzer proposed a macroscopic creep-induced anisotropy based on the FeNbSiBCu nanocrystal system. The creep anisotropy mainly comes from the magnetoelastic anisotropy of bcc-Fe(Si) nanocrystals caused by the tensile back stress of the amorphous matrix undergoing inelastic deformation [53]. Regarding the exploration of the structural origin of creep-induced anisotropy, Suzuki et al. revealed the anisotropy of the structure factor by energy dispersive X-ray diffraction (EDXD), and proposed a bond orientation anisotropy model[54]; Ohnuma based on a variety of (Fe , Co, Ni)-based amorphous components confirmed the elastic strain essence of structural anisotropy, proposed a local bonding strength heterogeneity model, and attributed the structural origin of creep-induced anisotropy to the local magnetic field of strong bonding regions Elastic coupling [55-57]. Recently, Herzer applied tensile stress during the annealing and crystallization process of Fe73.5Cu1Nb3Si15.5B7, and found that the saturation magnetostriction coefficient λs decreases linearly with the increase of tensile stress, and changes from positive to negative[58- 59]. This discovery has injected new vitality into the further development of stress annealing. Therefore, stress annealing is not only an important means to improve or adjust soft magnetic properties, but also with the rapid development of advanced analysis and characterization techniques, the physical and structural theoretical mechanisms of creep-induced magnetic anisotropy can be further explored and improved.

4. Research progress of Co addition on iron-based amorphous/nanocrystalline soft magnetic alloys

In 1998, Willard et al obtained the alloy composition named HITPERM by adding Co element on the basis of FeMB (M=Zr, Nb, Hf) soft magnetic alloy [14]. The study found that the addition of Co element increased the saturation magnetic induction of the nanocrystalline alloy of the system, and at the same time increased the Curie temperature of the alloy, but also led to the deterioration of the soft magnetic properties. In recent years, in order to further increase the saturation magnetic induction of amorphous/nanocrystalline soft magnetic alloys, the replacement of Fe by Co has become an important method. In 2014, Xu et al. added an appropriate amount of Co element to the FePC composition, which not only improved the amorphous formation ability of the alloy, but also increased the Curie temperature of the alloy, and also improved the saturation magnetic induction of the alloy [60]. In 2017, Hou et al. successfully prepared FeCoPCCu nanocrystalline strips. When the Co element atomic percentage is 4, the comprehensive soft magnetic properties are the best [61]. In the same year, Zhang et al. added trace Co elements to the FeSiBPCu nanocrystalline system to increase the saturation magnetic induction of the alloy, and found that although the addition of excessive Co elements can increase the saturation magnetic induction of the alloy to a certain extent, it will lead to soft magnetic properties of the alloy. rapidly deteriorated [62]. It is not difficult to find through the research of previous researchers that adding Co element to the iron-based amorphous/nanocrystalline alloy system can effectively improve the saturation magnetic induction of the alloy, but at the same time, because the Co element itself has a large magnetic anisotropy, It will also lead to the rapid deterioration of the soft magnetic properties of the alloy sample, so the addition of Co element is often a small amount.

Amorphous soft magnetic materials and nanocrystalline soft magnetic materials have been the focus of scientific research workers since they came out. Whether it is amorphous soft magnetic materials or nanocrystalline soft magnetic materials, they are usually obtained by rapid quenching and then improved by heat treatment. performance. The heat treatment of amorphous soft magnetic materials is annealing below the glass transition temperature or crystallization temperature to eliminate the residual stress of the strips to improve soft magnetic properties, while nanocrystalline soft magnetic materials achieve partial crystallization through heat treatment to improve nanocrystalline soft magnetic materials. properties of crystalline soft magnetic materials. In order to continuously optimize the soft magnetic properties of materials, researchers mainly adjust the composition of alloy elements and improve the heat treatment process. The extension of the anisotropy model, while the field of optimizing soft magnetic properties using magnetic field/stress heat treatment processes while exploring new compositions has been seldom stopped. Therefore, the development of an amorphous soft magnetic material or nanocrystalline soft magnetic material with high saturation magnetic induction, low coercivity and high permeability by element adjustment and magnetic field/stress heat treatment process is not only crucial for commercial applications It is important, and it also expands the ideas for the subsequent exploration of amorphous/nanocrystalline soft magnetic materials.

As an important ferromagnetic element, Co element can be doped with a certain amount of Co element to increase the saturation magnetic induction of the alloy, which is very important for amorphous soft magnetic materials and nanocrystalline soft magnetic materials with relatively low saturation magnetic induction. However, the addition of Co element reported in the literature is relatively low, because although Co element can increase the saturation magnetic induction of the material to a certain extent, it will also greatly deteriorate the coercive force and magnetic permeability of the material. Therefore, through magnetic field/stress heat treatment, we use Co element to increase the saturation magnetic induction of the alloy while suppressing the negative influence of Co element to obtain a soft magnetic alloy with high saturation magnetic induction, low coercive force and high permeability. Material. In this paper, on the basis of the classical system FeSiBCu developed by Ohta et al. in 2007, Co element was used to replace Fe element, and magnetic field heat treatment and stress heat treatment were used to improve the coercive force and magnetic permeability of the alloy, so as to obtain a non-metal alloy with excellent comprehensive soft magnetic properties. crystal soft magnetic alloy. The above-mentioned FeCoSiBCu system is doped with an appropriate amount of P element, and the magnetic field heat treatment is used to explore the nanocrystalline soft magnetic alloy with excellent soft magnetic properties.

The specific research contents are as follows:

(1) Adjust the content of Co element in the Fe82.65-xCoxSi2B14Cu1.35 alloy system, prepare FeCoSiBCu series amorphous strips, and study the thermodynamic influence of Co element on the alloy system; perform ordinary heat treatment and magnetic field heat treatment on FeCoSiBCu amorphous strips , to test and compare the soft magnetic properties of amorphous and nanocrystalline states obtained by two different heat treatment methods; use TEM, MFM and synchrotron radiation and other characterization methods to deeply analyze the relationship between microstructure and soft magnetic properties.

(2) Use the amorphous strip prepared in (1) to conduct ordinary heat treatment and tensile stress heat treatment, and study the change of soft magnetic properties and hysteresis curve of the amorphous strip after stress heat treatment; combined with MFM and TMA and other characterization methods to analyze Effect of microstructural changes on soft magnetic properties and hysteresis curves.

(3) The Fe82.65-xCoxSi2B9P5Cu1.35 alloy system with a high nucleation point was obtained by adding an appropriate amount of P element, and the nanocrystalline soft magnetic alloy was obtained by ordinary heat treatment and magnetic field heat treatment. Through the test and comparison of its soft magnetic properties, in-depth The effect of magnetic field annealing on the soft magnetic properties of nanocrystalline alloys was analyzed.

5. Heat treatment process

Three annealing methods are mainly used in this paper: ordinary annealing, magnetic field annealing and stress annealing. In this paper, ordinary annealing is used as a comparative heat treatment process for magnetic field annealing and stress annealing. In order to ensure the accuracy and reliability of the experimental data comparison and reduce the interference of external uncontrollable factors, the same annealing device is used for ordinary annealing and magnetic field annealing and stress annealing respectively. Just don’t add magnetic field and stress during annealing. Therefore, two heat treatment processes, magnetic field annealing and stress annealing, are mainly introduced here.

Magnetic field heat treatment

The magnetic field heat treatment furnace is shown in the figure. The magnetizing device of this equipment is made of densely wound empty spiral copper tube outside the ordinary heat treatment furnace. After inputting DC stabilized voltage current through the DC welding machine in the copper tube, a magnetic field with constant direction and size and uniform distribution is generated in the furnace cavity. In this paper, The longitudinal magnetic annealing is adopted, that is, the direction of the applied magnetic field is the same as that of the strip, so there is no need to add a fixture.

The specific experimental method of magnetic field annealing is as follows: the amorphous alloy strip prepared above was cut into strips with a length of 60 mm and placed in a quartz tube matched with a tubular magnetic field annealing furnace. Vacuum to 5×10-3 Pa; when the temperature of the tube furnace rises to the required annealing temperature, push the quartz tube into the tube furnace and apply an external magnetic field at the same time. The quartz tube was quenched and cooled to room temperature to obtain a strip sample after magnetic field annealing. It is worth noting that the common annealing experimental procedure used as a comparative heat treatment process is basically the same as the magnetic field annealing, except that no external magnetic field is applied during the annealing process.

Stress heat treatment

In this paper, dynamic thermal analysis equipment is used to carry out stress heat treatment on the strip sample. The tensile fixture is selected in the DMA equipment, and the strip is cut into a length of about 40 mm and fixed in the tensile fixture. The value of the external stress applied to the strip during the heat preservation process, and argon gas was introduced during the experiment to prevent the strip from being excessively oxidized.

Effect of Co addition on microstructure and soft magnetic properties of FeSiBCu alloy under magnetic field annealing

Soft magnetic materials have become an indispensable part of modern life and are widely used in power transformers, motors, sensors and other fields. Iron-based amorphous/nanocrystalline alloys have attracted much attention due to their excellent soft magnetic properties such as high saturation magnetic induction (Bs), low coercive force (Hc), high magnetic permeability (μe), and low loss (P). . To date, the commercial grades FINEMET, NANOPERM and HITPERM have been successfully developed and widely used in electronic devices [8-11]. However, the relatively low saturation magnetic induction of nanocrystalline alloys compared with conventional silicon steel hinders the miniaturization of their applications. Therefore, while maintaining the excellent soft magnetic properties, researchers are also committed to improving the saturation magnetic induction of the alloy system. According to reports, the saturation magnetic induction Bs of FeSiBCu and FeSiBPCu nanocrystalline alloys is greater than 1.8 T, and the coercive force Hc is less than 10 A/m, but the harsh annealing process of these two systems has brought great challenges to industrial production [12-14 ]. Therefore, iron-based amorphous/nanocrystalline alloys with high saturation magnetic induction, as well as materials with excellent soft magnetic properties and suitable for industrial production are expected to be developed.

Although amorphous soft magnetic alloys have better toughness, lower annealing temperature and simple annealing process, their soft magnetic properties are still underestimated due to their relatively low saturation magnetic induction Bs (<1.72 T) [68] . It was found that replacing Fe with Co could effectively improve the saturation magnetic induction Bs in amorphous and nanocrystalline alloys, but the increase in the content of Co would seriously affect the soft magnetic properties of the alloy, which was mainly attributed to the high content of Co magnetic anisotropy [44,60-62,69-70]. Recently, Zhao et al. used longitudinal magnetic field annealing to improve the soft magnetic properties of amorphous alloys with a high content of Co. Therefore, by means of magnetic field/stress heat treatment methods such as magnetic field annealing, they developed an alloy with high saturation magnetic induction Bs and excellent soft magnetic properties. The alloy system is of great significance [44]. To this end, we combined the magnetic field annealing, a magnetic field/stress heat treatment method, in the Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) alloy system to study the thermodynamic properties, soft magnetic properties and The influence of the microstructure.

Soft magnetic properties of Fe82.65-xCoxSi2B14Cu1.35 alloy annealed for a long time

As mentioned in the introduction, we aim to prepare an alloy system with excellent soft magnetic properties and suitable for industrial production. The annealing temperature Ta of the alloys in this paper is lower, which is better It is beneficial to save energy, but considering that the experimental annealing time ta is 15 minutes, the annealing time ta is relatively short in industrial production, and it is not easy to realize. Because through the above analysis, the best performance of Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) alloy is amorphous structure, and the annealing time is easy to control. For this reason, we extended the annealing time ta to 1 hour, and evaluated the soft magnetic properties of the samples, as shown in Table 3-2 [8-12]. We annealed all the samples at 300 °C for 60 min in a magnetic field, and their soft magnetic properties were not much different from the best performance at 15 min in the previous article. Taking x = 16 as an example, after magnetic field annealing at 370 °C for 15 min, the saturation magnetic induction Bs is as high as 1.86 T, the coercive force Hc is 1.2 A/m, and the effective permeability μe is as high as 16300; at 300 °C for 60 min, the saturation magnetic induction Bs is as high as 1.85 T, the coercive force Hc is 1.8 A/m, and the effective permeability μe is as high as 14600. Compared with the traditional nanocrystalline system, the Fe82.65-xCoxSi2B14Cu1.35 alloy system has excellent soft magnetic properties, high saturation magnetic induction Bs, low annealing temperature Ta, and controllable annealing time ta. Advantage.

In this chapter, the soft magnetic properties of the alloy samples are systematically studied by adding an appropriate amount of Co element to Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) combined with the magnetic field annealing process, and combined with TEM, MFM, VSM and other instruments. The change of the soft magnetic properties of the alloy is analyzed in detail, and the effect of the external magnetic field is studied in depth. The specific experimental conclusions are as follows:

(1) With the increase of Co element content, the thermal stability of Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) alloy system increases. The increase of Co element content also effectively increases the Curie temperature TC and saturation magnetic induction Bs of alloy amorphous state.

(2) For amorphous structure alloys with high Co element content, the external magnetic field can well adjust the magnetic domain order inside the alloy during the annealing process, so that the magnetic domains are arranged regularly and the pinning effect is greatly reduced. Magnetic field annealing FA well adjusted the soft magnetic properties of amorphous alloys.

(3) Through step-by-step annealing experiments, it was found that even if the crystallization volume fraction of α-Fe in nanocrystals is small, the random anisotropy model still plays a dominant role in the soft magnetic mechanism of nanocrystals, and the grain size and distribution determine the Soft magnetic properties of nanocrystals.

(4) Compared with ordinary annealed NA, magnetic field annealed FA can further increase the saturation magnetic induction Bs of the alloy by promoting the precipitation of α-Fe crystals and enhancing the structural order of the alloy.

(5) The Fe66.65Co16Si2B14Cu1.35 amorphous alloy has a high saturation magnetic induction Bs of 1.86 T, a low coercive force Hc of 1.2 A/m, and a high effective permeability μe of 16300, and because of its low annealing temperature Ta and the adjustable annealing time ta are conducive to better energy saving and industrial production.

6. Effect of Co addition on soft magnetic properties and microstructure of FeSiBPCu nanocrystalline alloy under magnetic field heat treatment

In the previous chapter, we obtained the FeCoSiBCu amorphous soft magnetic alloy with excellent soft magnetic properties through magnetic field annealing and the addition of an appropriate amount of Co elements. The soft magnetic properties are poor. In 2009, Makino et al. added P and Cu elements to the FeSiB amorphous alloy, and reported a FeSiBPCu soft magnetic alloy with high saturation magnetic induction. The advantages of this system are that the precipitated grain size is well controlled by the competitive growth mechanism. size[13-14, 18], so we obtained the FeCoSiBPCu alloy system based on the FeCoSiBCu system based on the work of Kong et al. in 2012 by replacing the B element with an appropriate amount of P element, aiming at combining magnetic field annealing and adding an appropriate amount of Co element A FeCoSiBPCu nanocrystalline alloy with excellent soft magnetic properties was obtained [82].

This chapter studies the effect of Co addition on the soft magnetic properties and microstructure of nanocrystalline soft magnetic alloys under magnetic field heat treatment. Fe82.65-xCoxSi2B9P5Cu1.35 (x = 0, 5, 10, 15, 20) amorphous strip samples were successfully prepared by adding Co elements, and nanocrystalline soft magnetic materials with excellent soft magnetic properties were obtained by adjusting the external magnetic field At the same time, the necessary conditions for the application of magnetic field heat treatment in the application of nanocrystalline alloys were explored. The main conclusions are as follows:

(1) The addition of Co element can increase the crystallization temperature of the second phase in the FeSiBPCu system without changing the temperature of the initial crystallization phase, because Cu and P elements are easy to form Cu3P clusters, which can be used as α- Nucleation sites for the Fe phase.

(2) The FeCoSiBPCu system with no or low Co element is sensitive to the external magnetic field during heat treatment, and the magnetic field heat treatment can improve the soft magnetic properties of the sample, especially the magnetic permeability; the sample with high Co element is only in the The external magnetic field can effectively improve the soft magnetic properties of the alloy when the precipitated grain size is small. This is because the addition of Co element reduces the ferromagnetic exchange length Lex, making it difficult for samples with larger grain size to meet the necessary conditions in the Herzer model. However, no Co element or low Co element will not be affected because the ferromagnetic exchange length Lex remains unchanged or decreases slightly.

(3) The external magnetic field can well eliminate the magnetic anisotropy of the sample in the nanocrystalline soft magnetic alloy, reduce the pinning effect between domains and improve the soft magnetic properties of the alloy.

(4) Fe67.65Co15Si2B9P5Cu1.35 nanocrystalline soft magnetic strip samples with high saturation magnetic induction Bs of 1.80 T, low coercive force Hc of 1.3 A/m and high effective permeability μe of 16000 were successfully prepared.

(5) The research results provide some guiding significance for improving the soft magnetic properties of nanocrystals by using magnetic field heat treatment, and are expected to be further applied in industrial production.

7. Effect of Stress Heat Treatment on Soft Magnetic Properties and Microstructure of FeCoSiBCu Amorphous Alloy

Combining the research results of previous researchers, we have greatly improved the soft magnetic properties of Fe-based amorphous alloys containing Co elements through magnetic field heat treatment, and combined with synchrotron radiation to study the microstructure changes of amorphous alloys. The heat treatment method of magnetic field/stress has similarities with magnetic field heat treatment, that is, stress heat treatment. Compared with the field-induced anisotropy induced by an external magnetic field in the magnetic field heat treatment, the creep anisotropy generated by applying directional stress to the sample during the stress heat treatment also has a decisive effect on the soft magnetic properties of the sample. However, researchers The physical origin of the creep anisotropy induced by stress heat treatment is still inconclusive. In this chapter, we still choose the Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) alloy system for stress heat treatment, aiming to study the stress heat treatment in depth by comparing the data of soft magnetic properties after magnetic field heat treatment and synchrotron radiation. Effects on the soft magnetic properties and microstructure of amorphous ribbons.

Study on Soft Magnetic Properties of Fe82.65-xCoxSi2B14Cu1.35 Amorphous Alloy Strip after Stress Heat Treatment

Figure 5-2 is a schematic diagram of the change of coercive force Hc with heat treatment temperature Ta for x = 0 sample and x = 16 sample at a heat treatment temperature of 230-330 ℃ with 4 N tensile stress and without tensile stress. In order to ensure the accuracy of the experiment and the objectivity of the comparison between the samples, the stress-applied samples and the unstressed samples were subjected to the same batch of heat treatment. The unstressed sample is only clamped at one end of the strip, so as to ensure that only the experimental variable of the applied tensile stress exists. From Figure 5-2, it can be seen that the coercive force Hc of the sample with x = 0 or the sample with x = 16 after tensile stress heat treatment is lower than that of the sample without tensile stress heat treatment, indicating that tensile stress heat treatment can It is very good to improve the soft magnetic properties of Co-containing or Co-free amorphous alloys, which is different from the improvement of soft magnetic properties of amorphous samples by magnetic field heat treatment in Chapter 3, because magnetic field heat treatment is a necessary condition for improving the magnetic domain structure of samples The sample needs to have a higher Curie temperature Tc, and the Curie temperature Tc>heat treatment temperature Ta, but this necessary condition does not exist in the tensile stress heat treatment, indicating that the application space of the tensile stress heat treatment is more extensive than that of the magnetic field heat treatment. broad. One point worth noting in Figure 5-2 is that the x = 16 sample has a larger coercive force Hc than the x = 0 sample, which has been explained in Chapter 3, but we found that x = 0 and x = 16, the coercive force Hc of the sample after tensile stress heat treatment basically remains in the same range, which shows that the tensile stress heat treatment can also eliminate the large magnetic anisotropy caused by the addition of Co element, but The factors that really dominate the soft magnetic properties in amorphous samples are still worthy of our further exploration.

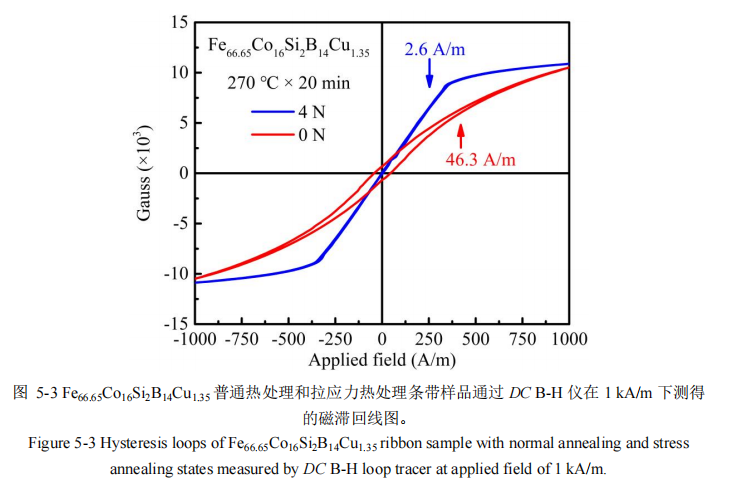

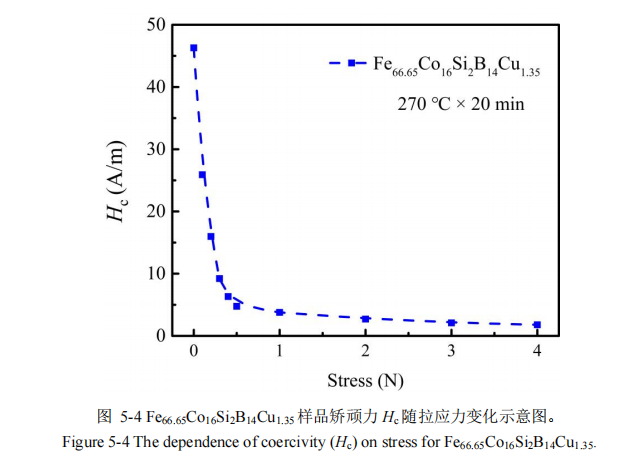

Figure 5-3 is the hysteresis loop diagram measured by DC B-H instrument at 1 kA/m after applying tensile stress and no tensile stress to Fe66.65Co16Si2B14Cu1.35 sample after heat treatment at 270 ℃ for 20 minutes. The red line in the figure is the hysteresis loop of the sample without tensile stress, and the curve has a small squareness, which is basically consistent with the hysteresis loop of the sample treated with ordinary heat treatment for 15 minutes in Figure 3-6(a), indicating that ordinary heat treatment does not apply There are more magnetic anisotropy with inconsistent orientation in the tensile stress heat-treated sample, so the soft magnetic properties are poor, and the coercive force Hc is 46.3 A/m. The blue line in the figure is the hysteresis loop of the sample after the tensile stress treatment of 4 N. The curve has a large squareness and strong linearity, indicating that the magnetic anisotropy of the sample after the tensile stress treatment tends to be consistent, so the soft magnetic The performance is relatively excellent, and the coercive force Hc is 2.6 A/m. It is not difficult to find that the hysteresis loop after tensile stress heat treatment is basically consistent with the hysteresis loop after magnetic field heat treatment. It can be speculated that tensile stress heat treatment can also improve the magnetic domain structure of the sample and adjust the magnetic domain order. Figure 5-4 is a schematic diagram of the change of the coercive force Hc of the sample corresponding to the application of different tensile stresses under the condition of heat treatment at 270 °C for 20 min for x = 16 samples. It can be seen from the figure that the coercive force Hc of the sample decreases most obviously when the applied tensile stress is 0-0.5 N, and the effect of improving the coercive force Hc tends to be stable in the range of 1-4 N applied stress. This shows that the amorphous sample is very sensitive to the applied stress, and even a small tensile stress in the heat treatment process can play a decisive role in the soft magnetic properties of the amorphous sample. Recently, Zhang et al. applied tensile stress in the process of measuring the coercive force of FeCoBPC system by DC B-H instrument, and found a similar conclusion to our experiment [19]. The difference is that the tensile stress of the sample in this experiment was applied during heat treatment. , so this improvement effect on the soft magnetic properties of the sample can be retained for a long time, but in Zhang et al.’s experiment, because the tensile stress was applied at room temperature, this improvement effect on the soft magnetic properties is difficult to last for a long time. maintain. Another difference from the experimental results of Zhang et al. is that Zhang et al. found that the soft magnetic properties deteriorated when the tensile stress was continuously applied at about 1-4 N to measure the coercive force Hc, while in this experiment it was a slight continuous decrease. It is very likely that the large tensile stress applied at room temperature has caused damage to the surface of the strip sample, resulting in the deterioration of the soft magnetic properties, and it may also be the reason for the elastic deformation and plastic deformation of the sample, which is also worthy of our in-depth exploration.

In this chapter, the Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) strip samples were subjected to tensile stress heat treatment and ordinary heat treatment by DMA equipment, and the thermodynamic and soft magnetic properties of the treated samples were tested to study the different The effect of Co element content sample on the improvement of tensile stress heat treatment on the soft magnetic properties of the same sample and the effect of different tensile stresses on the soft magnetic properties of the strip during heat treatment, the microstructure change of the amorphous strip sample was studied by means of synchrotron radiation and TMA ,

The main conclusions are as follows:

(1) The tensile stress heat treatment can effectively improve the coercive force Hc of the Fe82.65-xCoxSi2B14Cu1.35 (x = 0-20) strip sample, and with the increase of the Co content, the tensile stress heat treatment has a significant effect on the coercive force Hc of the sample. The improvement effect of recalcitrance Hc is more and more obvious. Through the observation of the hysteresis loop of the Fe66.65Co16Si2B14Cu1.35 strip sample, it is found that the tensile stress heat can adjust the internal magnetic domain structure of the amorphous sample and improve the overall order of the magnetic domain of the sample. Through the observation of the coercive force Hc of the samples after different tensile stress heat treatments, it is found that the soft magnetic properties of the amorphous samples are significantly improved when the applied stress is 0-0.5 N, and as the tensile stress continues to increase, the improvement effect tends to be gentle. (2) Through the synchrotron radiation observation of tensile stress heat-treated samples and ordinary heat-treated samples, it is found that the atomic distance of the sample after tensile stress heat treatment has changed, but it is known from the literature that this change in atomic distance does not mean that the sample structure is more relaxed or more stable. Tight, this is because of changes in the viewing surface.

(3) The thermal expansion behavior of tensile stress heat-treated samples and ordinary heat-treated samples was analyzed by TMA, and it was found that the thermal expansion coefficient of the tensile stress heat-treated samples was higher and rose faster during the measurement process, which may be related to “Invar “effect”, that is, the interaction between thermal expansion and magnetostriction of ferromagnetic amorphous samples, the tensile stress heat treatment may reduce the magnetostriction of the sample, so the soft magnetic properties are excellent, and the samples treated by ordinary heat treatment are due to their large magnetostriction. Therefore, the “Invar effect” occurs during the thermal expansion process, resulting in a low thermal expansion coefficient and a slow rise

Kerosene Vapor Phase Drying Process For 44MVA Transformer Study on Softening Annealing Process of Low Carbon Steel Wire High Temperature Fastener Heat Treatment Process

Contact us

Your email address will not be published. Required fields are marked *