Effect Of Magnetic Field Annealing On Structure And Properties Of Soft Magnetic Materials

Magnetic materials are ancient and widely used functional materials. The magnetic properties of materials were recognized and applied as early as 3000 years ago. For example, natural magnets were used as compasses in ancient China. Modern magnetic materials have been widely used in our lives, such as the permanent magnet material used as a motor, applied to the core material in the transformer, magnetic disc used as memory, computer magnetic record floppy disk. It can be said that magnetic materials are closely related to information, automation, mechatronics, national defense and all aspects of the national economy. Magnetic materials are divided into hard magnetic materials (also known as permanent magnet materials) and soft magnetic materials, which have low coercivity and high permeability low loss easy magnetization and easy demagnetization soft magnetic materials, widely used in electrical equipment and electronic equipment, is the most widely used, the most kinds of functional materials. According to different application situations, it can also be focused on some special performance requirements, such as high saturation strength, high maximum permeability, etc. The development of soft magnetic materials has experienced metal soft magnetic materials, ferrite soft magnetic materials, amorphous soft magnetic materials, nanocrystalline soft magnetic materials, nanoparticle structure soft magnetic materials and other stages. Metallic soft magnetic materials, mainly in the form of iron cores, are used in electrical and electronic equipment such as transformers, electromagnets, engines, generators and relays. The traditional metal soft magnetic materials are represented by silicon steel sheet, permalloy alloy and sendust alloy, including Fe series, Fe-Si series, Fe-Al series, Fe-Ni series, Fe-Si-Al series, Fe-Co series and Fe-Cr series. Soft magnetic ferrite material is composed of manganese, nickel, magnesium, copper and other bivalent metal oxides and Fe2O3 materials. There are many kinds of soft magnetic ferrites, among which manganese zinc ferrite and nickel zinc ferrite are the most widely used. Because the soft magnetic ferrite has the characteristics of high permeability, high resistivity and low loss at high frequency, and has the advantages of easy mass production, stable performance and high machining performance, the magnetic core of various shapes can be made by the mold. In particular, low cost makes soft magnetic ferrite mainly used as inductor and magnetic core in electronic industries such as communication, broadcasting, computer, radar and so on. The appearance of amorphous soft magnetic materials is a breakthrough in the development of soft magnetic materials. Amorphous materials do not have the same anisotropy as crystalline materials, that is, there is no grain structure that blocks the movement of magnetic domains, so it is easier to magnetize and demagnetize, so you can get greater permeability and less coercivity. The resistivity of amorphous material is 3~4 times higher than that of crystalline material, so the eddy current loss can be greatly reduced. Nanocrystalline soft magnetic alloy usually refers to single-phase or polyphase polycrystalline alloy with grain size of 1~50 nm with high permeability, low coercivity, small magnetic loss and good high frequency characteristics, but also has good mechanical properties, magnetoelastic properties and corrosion properties. Soft magnetic material as a basic functional material, with the development of power, electronics, aerospace and other fields, scientists also put forward higher requirements for it, high saturation magnetic induction Bs, high permeability μ, low coercivity Hc, low loss P, high Curie temperature Tc. In order to improve the performance of soft magnetic materials, researchers continue to improve the composition of materials, update the means of preparation of materials and secondary treatment of materials before application, among which magnetic field annealing of soft magnetic materials has attracted more and more attention.

1. Magnetic field annealing

Previous researches on magnetic field annealing mainly focus on obtaining specific shape hysteresis loop and changing static magnetic properties. For example, longitudinal magnetic field annealing can obtain high remanence ratio, while transverse magnetic field annealing can make hysteresis loop smoother. In recent years, the effect of magnetic field annealing on high temperature magnetic properties of nanocrystals has attracted more and more attention.

1.1 Mechanism of magnetic field annealing

Magnetic field annealing, also known as magnetic field heat treatment, in the process of heat treatment of materials to add a magnetic field. For soft magnetic materials, the effect of magnetic heat treatment on soft magnetic alloy can be regarded as adding a uniaxial magnetic anisotropy to the alloy, namely magnetically induced anisotropy (Ku). Since the anisotropy induced by magnetic field heat treatment of amorphous alloy is very similar to that of crystalline magnetic gold, and the maximum value of anisotropy is basically the same, the theory of atomic orientation order in Neel-Taniguchi crystal alloy [17] is often used as the uniaxial Ku anisotropy model for analyzing amorphous. The theory is based on the concept that different pairs of atoms present in magnetic alloys interact differently with each other. Thus, in a thermally activated system in which a magnetic field is present, pairs of atoms tend to align in the direction of the lowest total energy. Then, when the system cools to low temperatures, the atoms hardly spread any more and the orientation is — frozen — down, resulting in induced magnetic anisotropy. Figure 1-1 shows the atomic exchange model of Permo alloy (Ni-Fe alloy). During magnetic heat treatment, the positions of Fe and Ni atoms are interchanged, resulting in the appearance of Ni-Ni atom pairs. Thus, one Fe-Fe and one Ni-Ni atomic pair are added, while two Fe-Ni atomic pairs are decreased. This will affect the value of the energy change that occurs when one of the Ni-Fe atoms in parallel to the magnetization changes position with the other atoms, thus affecting the magnitude of the induced anisotropy constant. Therefore, the arrangement effect of atoms strongly influences the appearance of magnetoinduced anisotropy.

When the alloy is annealed at the appropriate temperature, a variable axis is generated in the sample. This axis is not only the direction of the external magnetic field that induces magnetic anisotropy, but also the direction of magnetization of the sample. When treating the temperature. When Tc is high enough, the average kinetic energy of the atoms in the alloy is relatively large, which is conducive to its own diffusion. Under the action of the magnetic field, its magnetic moment tends to the direction of magnetization. When cooling the room temperature, the atomic diffusion almost stops, and the external magnetic field is removed, the atomic direction ordering will be frozen, and the anisotropic energy will be increased in the macro.

The uniaxial anisotropy induced by magnetic field annealing is not very large in value, generally several hundred J/m3, and increases with the increase of alloy composition. The induced anisotropy increases with the increase of the types of elements in the alloy. For the homogeneous elements, there is no anisotropy. In addition, the magnitude of induced anisotropy is closely related to the annealing temperature of magnetic field annealing. The higher the temperature of magnetic field annealing is selected, the larger the induced anisotropy will be, because the higher the temperature, the more significant the atomic diffusion and the more obvious the arrangement of atoms along the direction of external magnetic field, so the larger the uniaxial anisotropy generated.

In the process of demagnetization, the magnetic domains of the alloys after magnetic field annealing are arranged in order, and the magnetic moments of the domain tend to the direction of the external magnetic field in the annealing process. Under heating conditions, the magnetic moments in each domain are more active. According to the principle of minimum energy, the magnetic moments will tend to be in the same direction as the external field under the action of the external magnetic field. When the external magnetic field is weak, the magnetic moment inside the domain wall will converge with the direction of the external magnetic field, so that the domain with the magnetic moment of the same direction of the external magnetic field will grow, and the domain with the direction of the external magnetic field will gradually shrink, so that the domain as a whole toward the direction of the external magnetic field. When the external magnetic field is strong, the magnetic moments in each domain will be forced to shift towards the external magnetic field. As the heating temperature drops, this domain wall movement, or magnetic moment rotation, freezes into the material.

1.2 Development of magnetic field annealing

At present, there are many types of magnetic field annealing, including: longitudinal magnetic field annealing, transverse magnetic field annealing and rotating magnetic field annealing, as well as strong constant magnetic field treatment, pulsed magnetic field treatment and other magnetic field annealing methods. Magnetic heat treatment has received more attention. Magnetic field treatment can significantly improve the magnetism, which can greatly improve the microstructure of dual-phase nanocrystalline composite permanent magnet materials [27], strengthen the exchange and coupling effect between grains, and improve the magnetic properties of the materials. In 1913, Pender and Jones et al. annealed 4% Si-Fe alloy with AC magnetic field at 800℃. When the annealing temperature dropped to room temperature, it was found that the permeability of the material was significantly improved. In 1934, G. A.Kelsall, an American, conducted magnetic field annealing on Permo alloy and found that the maximum permeability was greatly improved [28]. In 1951, Goertz in the United States measured the maximum permeability of 65% silicon steel single crystals after magnetic field annealing, and found that, relative to non magnetic field annealing, along < 100> The maximum surface permeability is increased from 50×103 to 3.8×106[29]. In 1988, Yoshizawa et al. from Hitachi Metal Company in Japan found Finemet alloy with excellent soft magnetic properties, then Yoshizawa applied magnetic field annealing technology in the heat treatment process of Finemet nanocrystalline alloy, and found that for nanocrystalline soft magnetic alloy, Appropriate magnetic field annealing treatment can significantly improve the shape of its hysteresis loop, making the soft magnetic properties of materials change in the direction required by people [30]. In 2005, K. Suzuki et al. carried out rotating magnetic field annealing on FeNbB nanocrystalline soft magnetic alloy, and the experimental results showed that the coercivity of the alloy was significantly reduced by rotating magnetic field annealing.

1.3 Magnetic field annealing of nanocrystalline alloys

Longitudinal magnetic field annealing was performed on annular samples and strip samples. Annular samples were annealed in AC longitudinal magnetic field annealing furnace, while strip samples were annealed in DC magnetic field annealing furnace. Dc magnetic field and AC magnetic field have the same effect on the magnetization of soft magnetic materials, and the AC magnetic field annealing of annular sample and the DC magnetic field annealing of strip have the same effect [47]. The magnetic field annealing temperature is generally set in the highest possible range below the Curie point of the alloy. When the annealing temperature is too low, the atoms cannot be fully diffused, which is not conducive to the ordered arrangement of magnetic atom pairs, so that the uniaxial anisotropy can not be formed effectively. The annealing temperature is higher than the Curie temperature, and the internal magnetic domain arrangement of the alloy is paramagnetic, and the external magnetic field has no obvious effect.

1.3.1 Longitudinal magnetic field annealing of annular sample

Device for annular sample magnetic field annealing furnace

The device is composed of heating system, magnetization system and gas protection system

(1) Heating system: It is composed of annealing furnace cavity, heating circuit and temperature measuring device.

There is a heating electric furnace wire around the annealing furnace cavity, and after electrifying, the sample is heated by heating the electric furnace wire. In order to avoid the influence of the magnetic field generated by the electric furnace wire on soft magnetic materials, the electric furnace wire is double-wound. The current of each pair of windings is equal in magnitude and opposite in direction, while the magnetic field generated by the double winding coil is just opposite, so that the magnetic fields can cancel each other.

Since there is no electric heating wire at either end of the furnace, the cooling rate at both ends of the corundum tube is faster than that in the middle. In order to keep the temperature balance in the furnace as much as possible, the electric heating wire should be wound so that the two ends should be dense and the middle should be open, so that a section of uniform temperature zone can be obtained in the central area of the furnace tube. In order to keep the furnace warm at annealing temperature for a period of time, we wrapped the electric heating wire with asbestos cloth as the insulation layer. After the electric furnace wire was connected to the power supply, the sample was heated. In order to avoid the oxidation of the sample during the heating process, argon gas was passed into both ends of the furnace tube as the sample protection gas, and vacuum sealing mud was used to seal the interface of each gas guide pipe.

(2) Magnetization system: composed of copper rod, voltage regulating transformer, etc.

In order to realize the longitudinal magnetic field annealing of the annular sample, a magnetic field needs to be provided along the direction of the sample circumferential system. The linear current carrier just generates the annular magnetic field around the linear carrier. Therefore, a copper rod with a diameter of about 12mm is used as the magnetic field generating device. In order to obtain A high AC current of 100 A without damaging the electronic components in the heating device, the copper rod is energized by a two-stage step-down method in the experiment. The specific way is: first an adjustable transformer will reduce the 200 V AC to 30-50 V, and then by an unadjustable transformer for secondary voltage reduction, so as to obtain low voltage, high current AC. The current through the copper rod is controlled by A voltage regulator. When the voltage value is about 40 V, the current of the copper rod can be raised to 100 A. In practice, when the copper rod passes through the current of 100 A, the heat of the copper rod is not large, and the current between the two transformer stages is maintained between 6 and 7 A, which will not cause any damage to the line and the devices.

Experimental procedure for longitudinal magnetic field annealing of annular samples

(1) Put the nanocrystalline alloy annular sample on the carrier, and push the carrier to the uniform temperature area in the furnace.

(2) Check the air tightness and protective gas ventilation of both ends of the line and furnace tube.

(3) Turn on the heating power supply, continuously increase the heating current, so that the furnace temperature, through the thermocouple and digital thermometer to observe the temperature in the furnace. The heating current should not exceed 10 A, generally 8-9 A. At the same time, the argon ventilation valve is opened. When the temperature in the furnace is below 80°C, the argon ventilation can be reduced. When the temperature is further increased, the argon ventilation can be gradually increased.

(4) When the temperature in the furnace rises close to the Curie temperature of the sample, turn on the magnetic field generating device, adjust the voltage of the primary transformer to about 50 V, and measure the current through the copper rod with A clamp meter to keep it at about 100 A.

(5) The cooling process should be as slow as possible, so in the cooling process of the right voltage regulator transformer to slowly depressurize. When the temperature drops below 200oC, reduce the ventilation, and the temperature drops to around 60oC to cut off the magnetic field and close the argon gas bottle.

(6) When it is reduced to room temperature, all the power supply is cut off, the carrier can be pulled out with traction line, and the sample is then taken out. In addition, it should be noted that the sample with higher Curie temperature generally does not need to be kept warm, so that the temperature in the furnace can be slowly lowered to room temperature. The sample with lower Curie temperature should be kept warm for an appropriate time and then slowly lowered to room temperature to ensure the full diffusion of atoms.

1.3.2 Longitudinal magnetic field annealing of strip samples

Device with annealing furnace

The strip annealing furnace is composed of heating device, magnetizing device, gas protection device and cooling device.

(1) Heating device: It is composed of annealing furnace tube, heating circuit and temperature measuring device.

A high temperature resistant (1600oC) corundum tube with an outer diameter of 30 mm and an inner diameter of 22 mm is used as the annealing furnace tube, sealed with rubber plugs at both ends. The electric heating wire is wound on the furnace tube, and the current value in the line is controlled by adjusting the voltage of the adjustable transformer to heat the furnace tube. The current should not exceed 10 A. The winding mode of electric heating wire is double winding. The temperature in the furnace is read by the thermocouple, and the annealing temperature is determined by the Curie point of the material. The selection of annealing temperature is similar to that of the longitudinal ring sample, which is as high as possible below the Curie temperature. If the Curie temperature of the material is low, it can be held at the annealing temperature for 10 to 30 minutes. If the Curie temperature is high, it can be cooled after reaching the Curie temperature. In order to magnetize the sample to saturation, the cooling rate should not be too fast.

(2) Magnetization system: It is composed of tightly wound helical coil, DC power supply and Tesla meter.

The tightly wound solenoid is CJS1 three-purpose solenoid. After direct current is passed into the solenoid, the stable magnetic field produced in the tube can run through the annealing furnace tube. The maximum allowable direct current of the solenoid is 12 A, and the maximum output current of the DC regulated power supply is 4.2 A, which will not cause damage to the solenoid. It is measured by the Tesla meter that the magnetic field size in the current tube is about 40 mT, which can magnetize the slender strip sample to saturation, and has the same effect as the AC longitudinal magnetic field annealing of the annular sample.

The magnetic field as shown in the figure is generated in the solenoid after the DC regulated power supply is supplied. In the experiment, the strip sample is placed along the magnetic field direction, so that the longitudinal magnetic field annealing can be carried out on the strip sample. When measuring the magnetic field in the tube, place the Tesla meter pen on the edge of the inner wall of the solenoid and observe its indication. The size of the central magnetic field inside the solenoid is twice that of the edge magnetic field [48], so the size of the central magnetic field inside the solenoid can be estimated. In general, it is necessary to provide a magnetic field as large as possible to magnetize the sample to saturation. In operation, the magnetic field in the central region is actually around 36 mT.

(3) Gas protection system: composed of high purity argon and ventilation tube.

In order to prevent oxidation of the sample in the heating process, argon gas should be introduced into the furnace tube as a protective gas. In the experiment, the gas ventilation rate of argon is usually controlled by controlling the bubble discharge rate. At low temperature, a small amount of argon can be introduced, one bubble per second, and the gas ventilation rate of argon should be increased appropriately at high temperature.

(4) Cooling protection system: composed of coiled copper pipe and circulating water pipe.

The annealing furnace is different from the AC magnetic field annealing furnace. The heating furnace tube is placed in the electrified solenoid, and the solenoid will be damaged at high temperature under the electric heating wire. In order to protect the solenoid and its shell from damage, a copper tube with good thermal conductivity is spiral wound on the annealing furnace tube, and circulating water is passed into the copper tube. Can form a heat insulation area between the furnace tube and the solenoid, play a protective role.

Use of longitudinal magnetic field annealing furnaces with strip samples

(1) The nanocrystalline alloy strip sample was placed in the carrier box and numbered. Push the iron box to the center of the annealing furnace and seal both ends of the annealing furnace.

(2) Check whether the circuit is well connected, check the air tightness of the furnace tube, and check the airtightness of each interface of the cooling circulating water.

(3) Turn on the cooling water, properly adjust the water flow size, turn on the argon gas, so that the bubbles in the water cup continue to emerge.

(4) Turn on the heating power supply and adjust the voltage regulating transformer to start heating. Generally, the current through the line is adjusted to 4 to 6A, and do not exceed 10 A. Observe the temperature in the furnace through the electric couple.

(5) When the temperature rises to a predetermined temperature, the voltage of the heating power supply can be reduced several times, so that the temperature in the furnace is slowly reduced to room temperature. For samples with low Curie temperature, they can be properly insulated for a period of time (10 minutes).

(6) Turn off the heating power supply, argon vent valve and cooling water, and take out the sample.

1.4 Theoretical analysis of the influence of magnetic field annealing on the saturation magnetostriction coefficient of nanocrystalline alloys

After magnetic field annealing, the saturation magnetostriction coefficient of FeCo- based nanocrystalline alloys decreases to different degrees. The effect of magnetic field annealing on saturation magnetostriction coefficient is analyzed from two aspects of stress and magnetic domain.

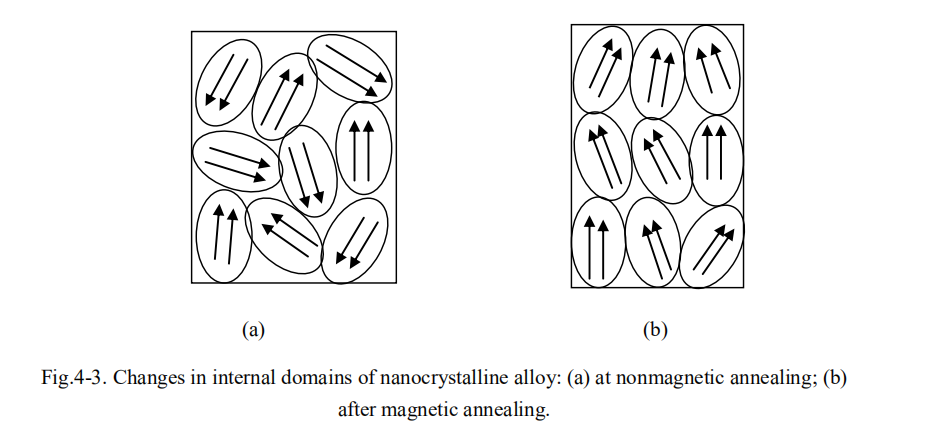

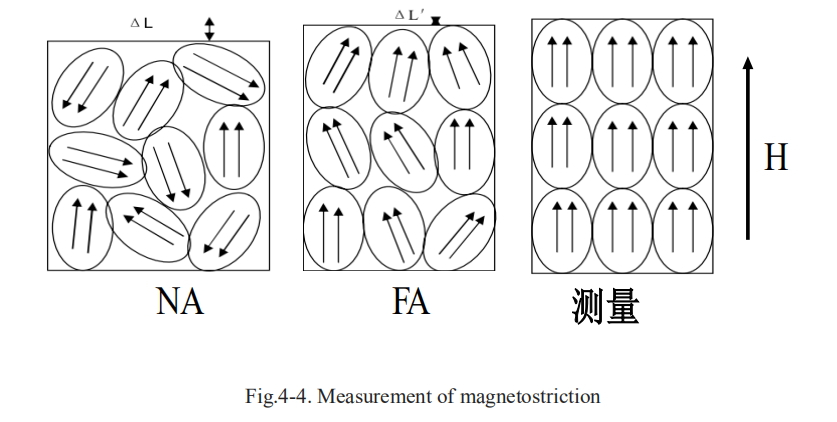

After the magnetic field is annealed, the magnetic domain is arranged in order under the action of the external magnetic field. The principle of magnetostriction is to measure the length change in the direction of an external magnetic field. The domains of the vacuum annealed alloy are randomly arranged [Figure 4-3(a)]. During the measurement, both 180° and 90° domain wall shifts occur, resulting in a large variation in the length of the alloy (Figure 4-4), so the saturation magnetostriction coefficient is large. For the alloy after magnetic field annealing, the average kinetic energy of the molecules is relatively large during the heating process, which is easy to diffuse. When the external magnetic field is added along a certain direction, the preferred orientation of the magnetic atom pairs is provided. In order to minimize the energy of the internal magnetic moment of each magnetic domain, the magnetic moment in the domain will gradually turn toward the direction of the external magnetic field. Align the magnetic moment roughly in the direction of the external magnetic field. In the process of cooling from high temperature to room temperature, if the magnetic moment is added along the direction of the external magnetic field, it will freeze in the alloy. In the measurement process (measured along the direction of the original magnetization), the 180° domain wall displacement mainly occurs in this direction, and almost no 90° domain wall displacement occurs, that is, the degree of magnetic moment steering is weak, resulting in weak crystal shape change. In this way, the length of the alloy changes less (as shown in Figure 4-4), so the magnetostriction becomes smaller. To graphically describe the above process, the following model is established to illustrate the effect of magnetic field annealing on magnetostriction of soft magnetic alloys, as shown in Figure 4-4, where arrows represent the direction of magnetic moments in each magnetic domain.

As shown in FIG. 4-4, when the alloy is not annealed by the magnetic field, due to the effect of the measured magnetic field H, the magnetic domain turns during the measurement of magnetostriction, thus driving the crystal length change, ΔL is the length change. After magnetic field annealing, the magnetic domains of the samples were aligned along the direction of the external magnetic field. When a measured magnetic field H was added in the direction, the rotation amplitude of the magnetic domains became smaller. The length change in the measurement process can be represented by ΔL ‘, and it can be seen that ΔL ‘is significantly less than ΔL.

1.5 Theoretical analysis of effect of magnetic field annealing on effective anisotropy of nanocrystalline alloys

In the process of magnetic field annealing, the magnetic moments in a large number of magnetic domains in the alloy are parallel to or tend to the direction of the external magnetic field, and then an axial direction is formed in the direction of the easy magnetization, that is, a uniaxial anisotropy parallel to the external magnetic field will be induced after magnetic field annealing (generally represented by Ku). The effective magnetic anisotropy of biphasic nanocrystalline alloys results from the competition between the effective magnetic anisotropy and induced anisotropy.

1.6 This chapter mainly studies the influence of magnetic field annealing on the saturation magnetostriction coefficient and effective anisotropy of Feco-based nanocrystals, and analyzes the mechanism of the influence, and draws the following conclusions:

(1) Compared with vacuum annealing, the λS of nanocrystalline alloy after magnetic field annealing is reduced to different degrees.

(2) The effective magnetic anisotropy is affected by the volume fraction and average grain size of the crystalline phase.

(3) Effective anisotropy of nanocrystalline alloys can be improved by magnetic field annealing due to induced anisotropy.

(4) The maximum effective magnetic anisotropy of Fe:Co=1:1 nanocrystalline alloy is obtained.

QPQ Nitriding Process Experiment And Heat Treatment Process of 42CrMo Piston Rod Study on Soft Magnetic Properties of Iron-Based Amorphous/Nanocrystalline Alloys Under Magnetic Field/Stress Heat Treatment Microstructure Transformation of Nanocrystalline Ni3Al During Low Temperature Annealing

Contact us

Your email address will not be published. Required fields are marked *